go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for OEM Supply Popular In South Africa Ibr Roofing Sheet Roll Forming Machine s, We will offer high-quality goods and great solutions at competitive price ranges. Start benefiting from our comprehensive services by contacting us today.

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for Galvanized Roofing Sheet Roll Forming Machine, Roll Forming Machine s, Roofing Sheet Making Machine, Selling our solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

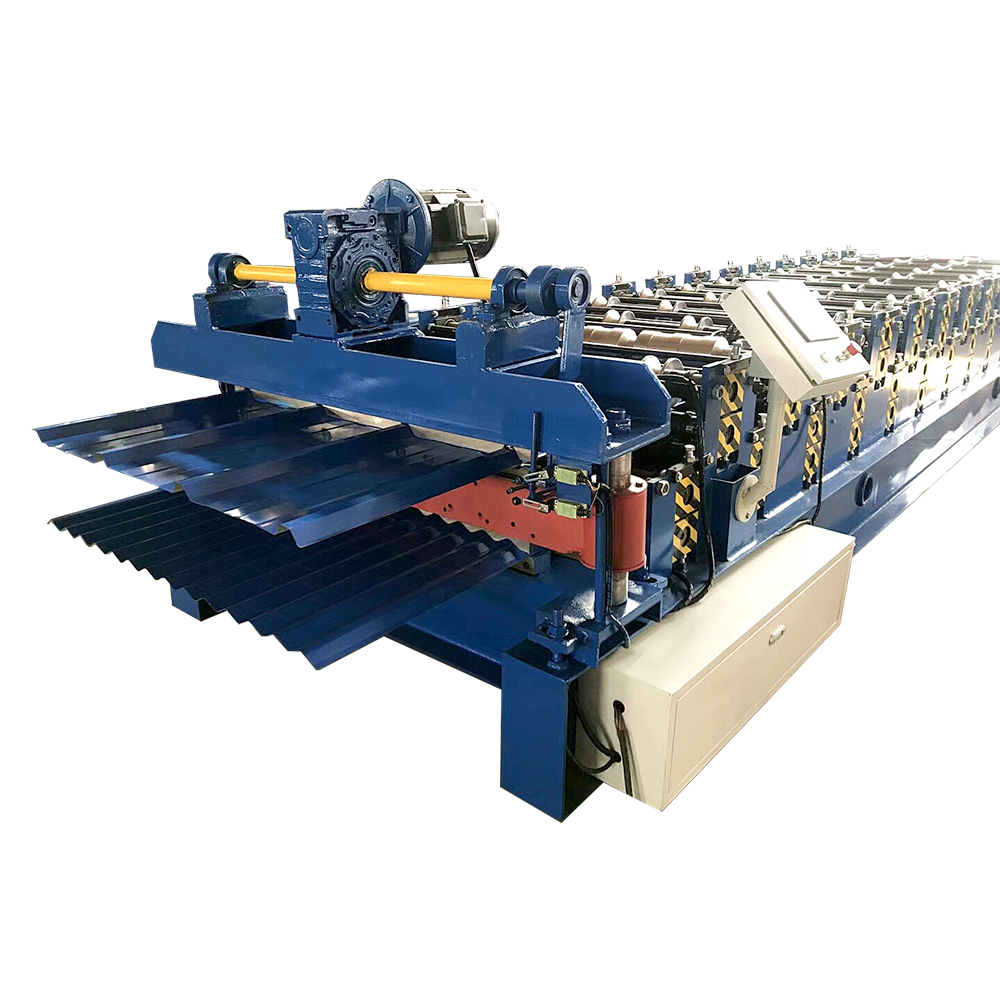

The trapezoidal tile double roll forming machine adopts high-level automatic control software to realize production information management.

Parameters of double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

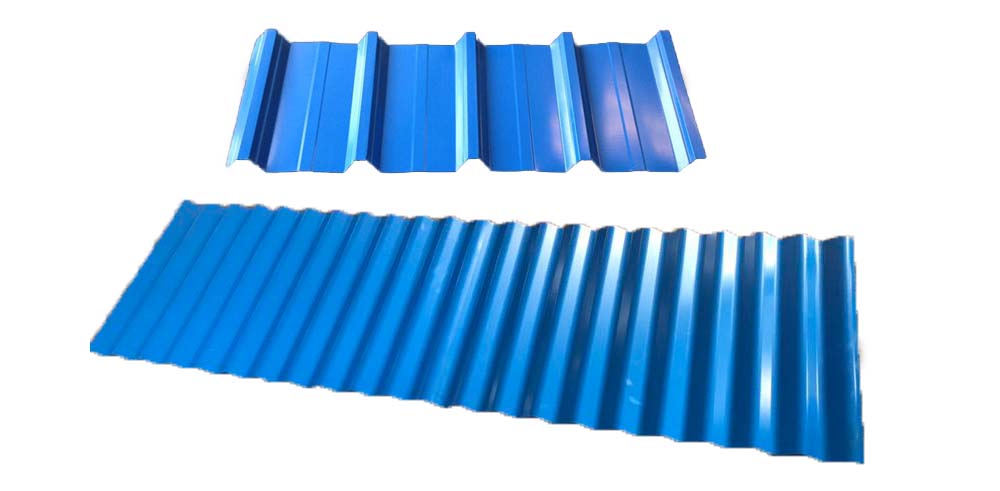

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Machine photos

Components of double layer corrugated roof sheet making machine

| No. | Name | Unit | Quantity |

| 1 | Manual decoiler | Set | 1 |

| 2 | Main forming machine | Set | 1 |

| 3 | PLC control system | Set | 1 |

| 4 | Hydraulic pump station | Set | 1 |

| 5 | Post cut | Set | 1 |

| 6 | Electric motor | Set | 1 |

| 7 | Output table | Set | 1 |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our company owned professional design team, we can design different profile according customer’s demands.

FAQ

Q:Are you a manufacturer?

A:Yes absolutely. Welcome a lot for your visiting to us.

Q:What’s the delivery time?

A: Normally will take 60 days, for small lines will take 30 days.

Q:Do you have after-sale support?

A:Yes, we’re always here for giving you advice and support for technical details since we have senior technician.

-

Quots for Double Layer Corrugated Roof Sheet Ma...

-

Manufacturer of Metal Studs Track Roll Forming ...

-

OEM Customized Color Steel Corrugated Plate Met...

-

OEM/ODM Manufacturer Cold Steel Sheet Uncoiler ...

-

OEM China Heat Treatment Cutter Roof Panel Tile...

-

Renewable Design for Aluminium Door Frame Makin...