Together with the “Client-Oriented” enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for OEM Supply Metal Roof Panel Roll Forming Machine, We are honest and open. We look ahead to the stop by and setting up trustworthy and long-term standing romantic relationship.

Together with the “Client-Oriented” enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for Metal Roof Panel Roll Forming Machine, Our items are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, you should contact us today. We are going to sincerely create and share success with all clients.

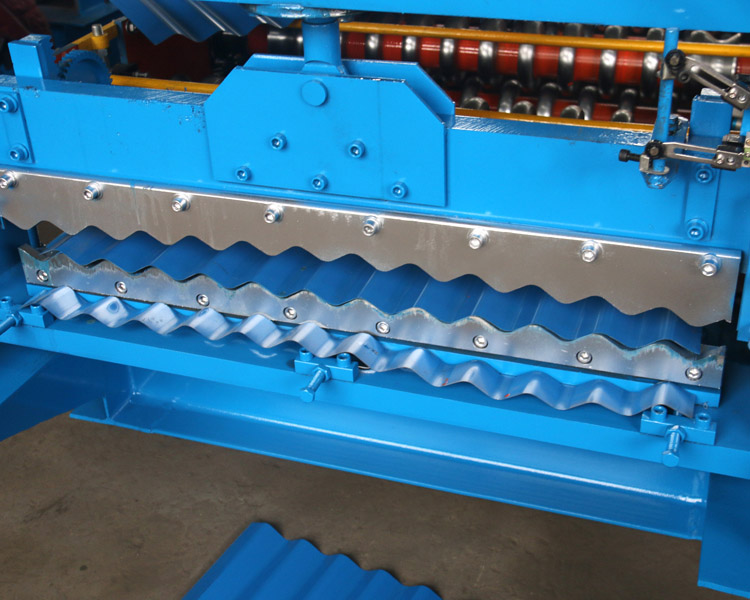

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Hot New Products China CNC Cold Bending Roll Fo...

-

Manufacturer for Galvanized Steel Ridge Cap Til...

-

High Performance Hot Sale Hydraulic Roof Tile H...

-

High Quality Hydraulic Cutting Metal Wall Panel...

-

Factory Cheap Hot Automatic Light Steel Keel Ro...

-

Short Lead Time for Glazed Tile Arch Curving Ro...