OEM Manufacturer Steel Tile Machine - Newly Arrival Roller Shutter Door Roll Forming Machine – Haixing Industrial Detail:

We often persist with the theory “Quality To start with, Prestige Supreme”. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Newly Arrival Roller Shutter Door Roll Forming Machine, We warmly welcome organization partners from all walks of lifestyle, assume to determine friendly and cooperative business enterprise get hold of along with you and achieve a win-win aim.

We often persist with the theory “Quality To start with, Prestige Supreme”. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Roller Shutter Door Machine, Roller Shutter Forming Machine, Rolling Shutter Machine, Our solutions have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we’ve been sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Machine parameters

|

Roller shutter door roll forming machine |

||

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

| 9 | Manual uncoiled | Max. Capacity: 3000kgs

Manual decoiler |

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements are from famous suppliers of China. |

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

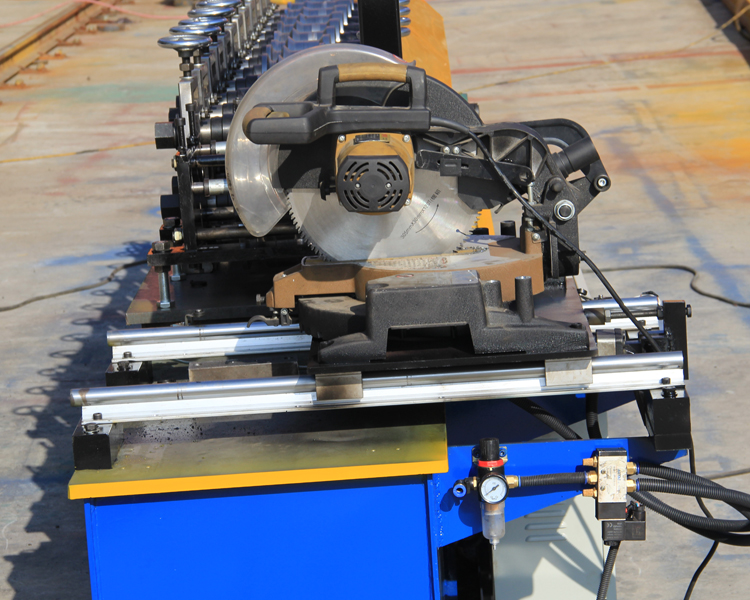

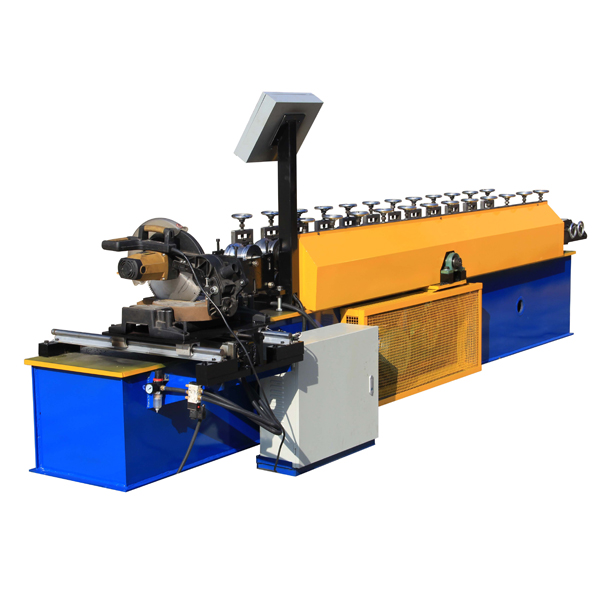

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.

Product detail pictures:

Related Product Guide:

Vellum Venom: 1992 Cadillac Brougham | Decoiler In Color Coating Line

This British mosque is structured with a flowering wooden lattice | Roof Sheet Curving Machine

OEM Manufacturer Steel Tile Machine - Newly Arrival Roller Shutter Door Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

China Factory for Electric Decoiler For 10 Ton ...

-

OEM/ODM Factory Pipe Making Machinery - Hydrau...

-

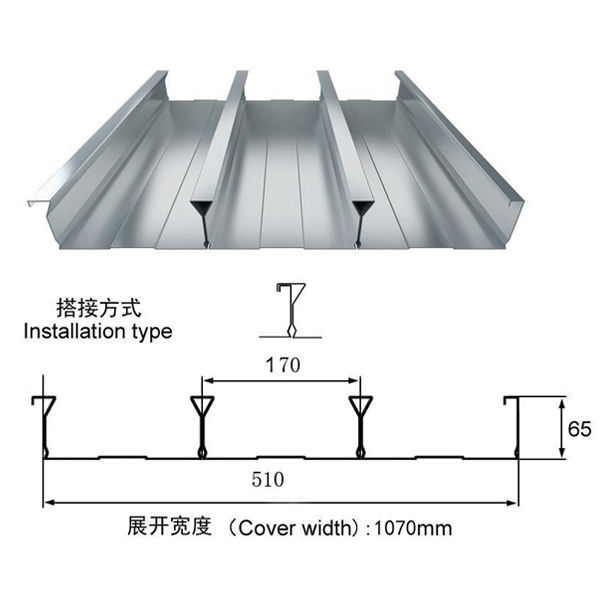

High Quality Galvanized Floor Deck Forming Mach...

-

New Fashion Design for C Z U Roof Channel Machi...

-

Newly Arrival Downspout Pipe Making Machine - ...

-

High Quality Gutters And Downspouts Pipe Formin...