Our pursuit and enterprise aim would be to “Always fulfill our buyer requirements”. We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for OEM Manufacturer China Suspension T Bar Ceiling Production Line, Seeing believes! We sincerely welcome the new prospects abroad to set up company interactions and also expect to consolidate the interactions with all the long-established clients.

Our pursuit and enterprise aim would be to “Always fulfill our buyer requirements”. We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for China Ceiling Tee Bar Ceiling Production Line, Tee Bar Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

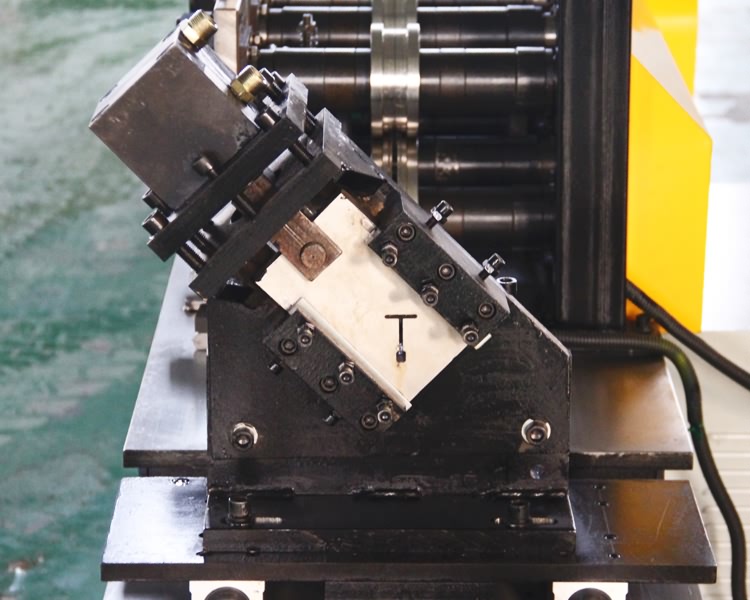

The cold-formed keel of t grid light steel keel roll forming machine is a kind of frame used to support the shape and fixed structure. The keel is the skeleton and substrate of the home decoration. It is very common to use and can be designed according to the buyer’s sample or drawings.

Components:

Manual decoiler ——————————————1 set

Guiding platform —————————————–1 set

Main machine of roll forming ————————–1 set

Electric motor ———————————————1 set

Cutting device ———————————————1 set

Hydraulic station ——————————————1 set

PLC control ————————————————1 set

Supporter table ———————————————1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).