Our business aims to operating faithfully, serving to all of our buyers , and working in new technology and new machine continuously for OEM Factory for Galvanized Steel Sheet Floor Decking Roll Forming Machine, Welcome your enquiry, very best company will be provided with full heart.

Our business aims to operating faithfully, serving to all of our buyers , and working in new technology and new machine continuously for Cold Roll Forming Machine, Floor Deck Macking Machine, Floor Deck Roll Forming Machine, Why we can do these? Because: A, We’ve been honest and reliable. Our goods have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will likely be highly appreciated.

The advantages of floor deck making machine

1. Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2. Controlling by computer, PLC display, operation is easy, running is steady and reliable, endurable, maintenance-free.

3. We can make and design will kinds of roll forming machine according to customer’s request.

Sales Service:

1.we provide technical support for the whole life of our machines.

2. If buyers need the technician to go abroad, we will arrange the technician, but the buyers should take all the cost, inculding visa, roundtrip ticket, etc.

The main technical parameters of Deck Floor Roof Sheet Roll Forming Machine

| Main Frame | welded with 450H steel |

| Middle plate | 18mm |

| Forming machine guide feeding frame form | side roller type |

| Forming machine form | wall plate chain drive |

| Shaft diameter | ¢95 mm |

| Chain size | 1.5 inches (Brand “Zhenghe” Imported Japan sprocket) |

| Roll forming machine motor power | 2-15KW (Brand Siemens) |

| Roll forming speed | 8-12m/min |

| Rollers number | 27Rows |

| Rolling material | high grade 45# forging steel with chromium plate |

| Hard chrome plating on the roll surface | 0.03mm |

| Hydraulic pump motor | 4KW (Lichao, Shanghai ) |

| Hydraulic station oil pump | gear pump |

| Cutting method | connecting rod three-knife hydraulic cutting |

| The material of the cutting blade | Cr12 |

| Cutting blade heat treatment | quenched treatment 58℃-62℃ |

| Rolling raw materials thickness | 0.7-1.2mm |

| Length Tolerance | ± 2mm |

| Electric control box configuration | inverter (anchuan), PLC (Panasonic), encoder (OMRON), Other electrical components are “Schneider” brand |

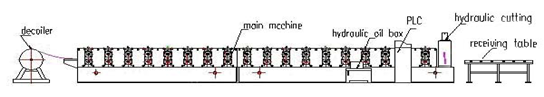

Deck Floor Roof Sheet Roll Forming Machine workflow

Deck Floor Roof Sheet Roll Forming Machine details

Application of decking floor tiles

Floor decking board products are widely used in power plants, power equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminals, railway stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, steel structures such as Olympic venues and stadiums.

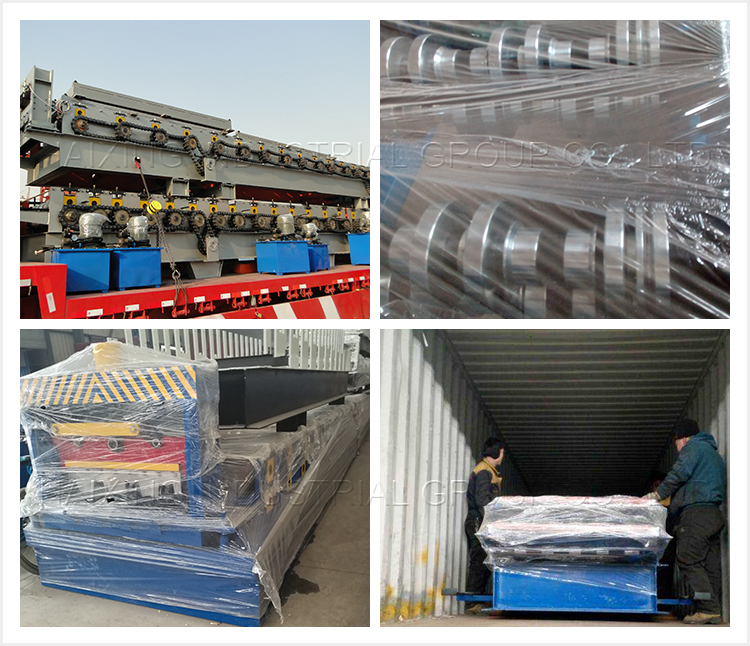

Deck Floor Roof Sheet Roll Forming Machine Packaging & Shipping

1. Main roll forming machine package by Plastic film ;

2. Main machine spare parts package by paper box ;

3. We have professional technicians for loading

Guaranteed the goods load into container without any damage.

4.Transportation: Machines need one 40 feet container to hold;

5. Please provide us the nearest port name, we will ask shipping cost and arrange to ship for you.

Our Services

a. 18 months warranty period, we will offer technical support for the whole life.

b. Engineer available to install machine and train your workers overseas.

c. 24hours open for you, any need and questions, we will reply to you as soon as possible.

-

10 Ton Hydraulic Decoiler With Coil Car

-

1xxx 3xxx 5xxx Series Aluminium Coil

-

1020 Trapezoidal Roof Sheet

-

1100mm steel tile roofing sheet roll forming ma...

-

2019 High Quality Glazed Tile Making Machinery ...

-

762 Corrugated Roof Metal Sheet Roll Forming Ma...

-

Roof tile making sheet metal machine aluminum d...

-

1000 Trapezoidal Metal Sheet Roll Forming Machine

-

2019 Hot Dipped Galvanized Steel Coil

-

6m Steel Bending Machine

-

762 Hot Sale aluminium wall sheet used metal ro...