Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for OEM Factory for Direct factory u profile roll forming machine metal roofing roll forming machine, To reward from our strong OEM/ODM capabilities and considerate companies, make sure you contact us today. We’re going to sincerely make and share success with all clientele.

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for , Our company is working by the operation principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can have a friendly relationship with businessman from all over the world.

r panel roll forming roof tile press machine’s technical parameters

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 9.5 tons |

| Voltage | 380V/50HZ/3Phase (as customer’s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 18mm |

| Drive mode | Chain Drice |

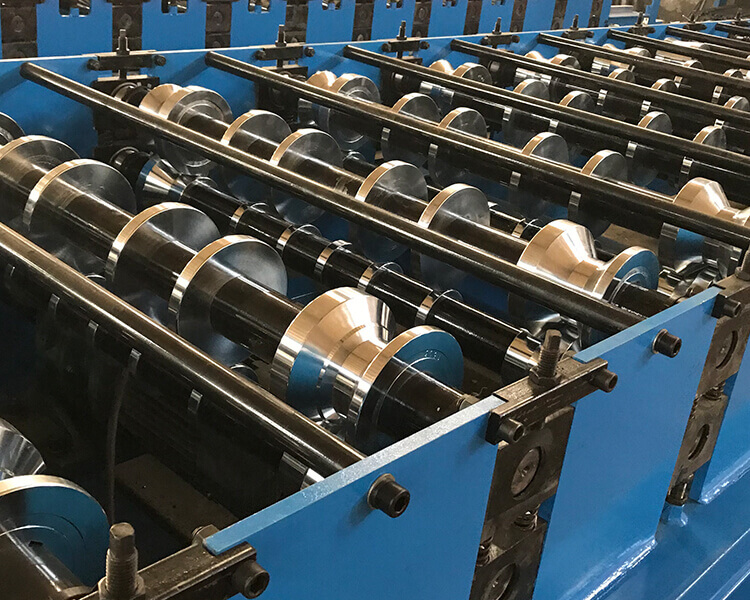

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 29 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Double guide pillar |

| Hydraulic motor power | 3kw,4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.8~1.5mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12/min |

| Package of machine | Waterproofing membrane, standard export packing |

r panel roll forming roof tile press machine’s introduction and feature

1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer’s requests.

Equipment placement:

The base surface of all equipment should be horizontal and hardened. The decoiler, roll forming machine ,center line of the discharge rack, molding machine and discharge table should be on the same straight line, and the left and right sides should not be inclined. The distance between the discharge rack and the forming host should be ≥3m. After the equipment is placed in a stable position, it should be fixed with anchor bolts.