OEM Factory for Closed Deck Floor Roll Forming Machine - Metal Sheet Highway Guardrail Roll Forming Machine – Haixing Industrial Detail:

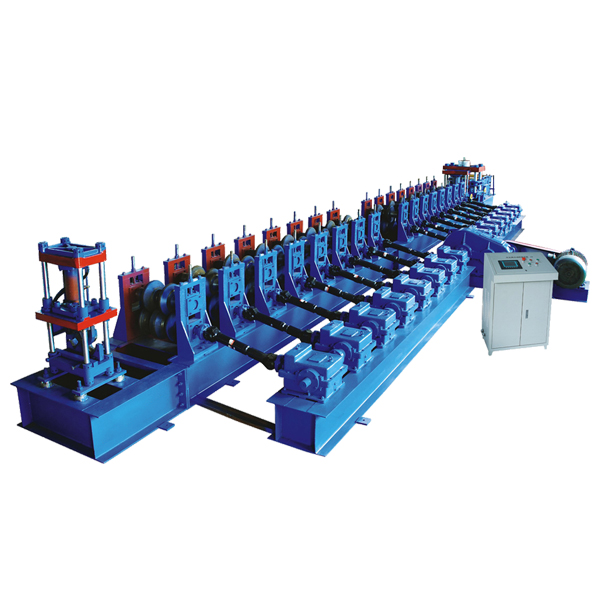

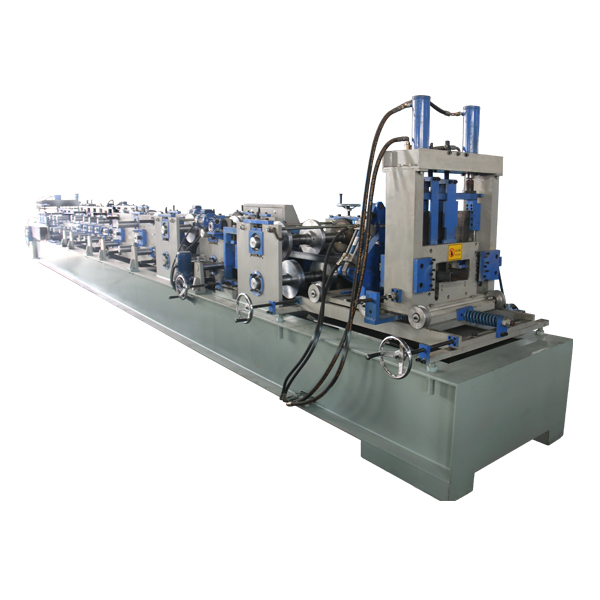

Metal sheet highway guardrail roll forming machine parameters:

| 1 | Suitable to process | Color steel plate, galvanized sheet, aluminum coils and etc. |

| 2 | Effective width | 310mm |

| 3 | Roller station | 17 rows forming, 7 roller leveling |

| 4 | Thickness of feeding material | 2.0-2.5 mm |

| 5 | Productivity | 8-12m/min |

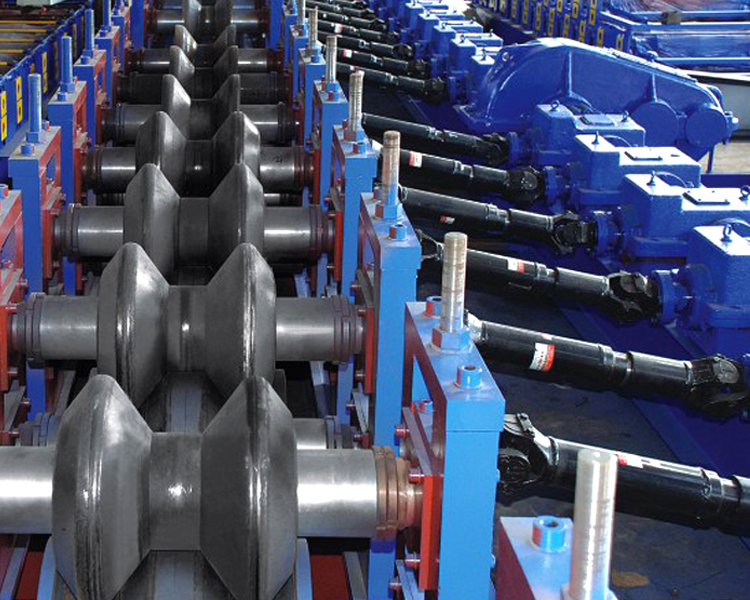

| 6 | Rollers’ material | 45# forging steel |

| 7 | Diameter of shaft | 100mm |

| 8 | Cutting tool material: | Cr12 with quenched treatment 60-62°C |

| 9 | Weight | About 6.9T |

| 10 | Size | 13.5*1.85*1.6mm |

| 11 | Voltage | 380V 50Hz 3phases |

| 12 | Wall thickness of main forming machine | 14mm steel plate |

| 13 | Main forming machine body | 300 mm H steel |

| 14 | Total power | 22+11 kw |

| 15 | Leveling power | 2.2 kw |

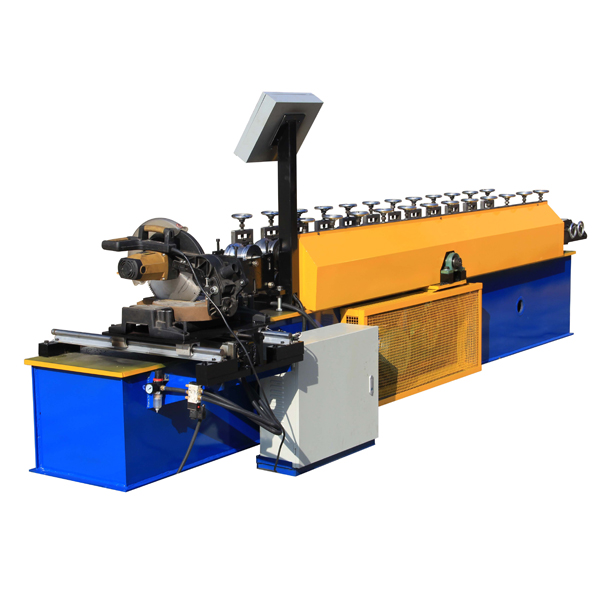

Machine picture display

Metal sheet highway guardrail roll forming machine details

The highway guardrail roll forming machine with good bending compression performance, flatness is good, and automatic fixed length cutting, automatic punching, high degree of automation, fast and convenient installation.

Package and shipment

Standard export packing: 1 x 40 GP container, main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

Product detail pictures:

Related Product Guide:

The Incredible True Story of the Henrietta C. | Ibr Roof Sheet Making Machine

Of Christmas, men’s stores and tape decks: Missoula 1968 | Local | Floor Deck Macking Machine

OEM Factory for Closed Deck Floor Roll Forming Machine - Metal Sheet Highway Guardrail Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

100% Original Standing Seam Roofing Machine - ...

-

Factory wholesale Water Gutter Channel Making M...

-

Factory making Roof Crimping Curving Machine -...

-

Personlized Products Steel Ceiling T Grid Roll ...

-

Competitive Price for Cnc Punching And Shearing...

-

100% Original Factory Rock Wool Board Productio...