We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for OEM Factory for 2018 Heavy Metal Roof Tile Forming Machine Popular, Should you be fascinated in any of our goods, make sure you really don’t wait to get hold of us and take the initial step to create up an effective company connection.

We not only will try our greatest to offer superb companies to just about every buyer, but also are ready to receive any suggestion offered by our shoppers for Metal Roll Forming, Roll Forming, Tile Forming Machine, Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our items will continue to increase in the order and look forward to cooperation with you, Truly need to any of people products be of interest for you, be sure to letus know. We are likely to be pleased to give you a quotation up on receipt of one’s in depth specs.

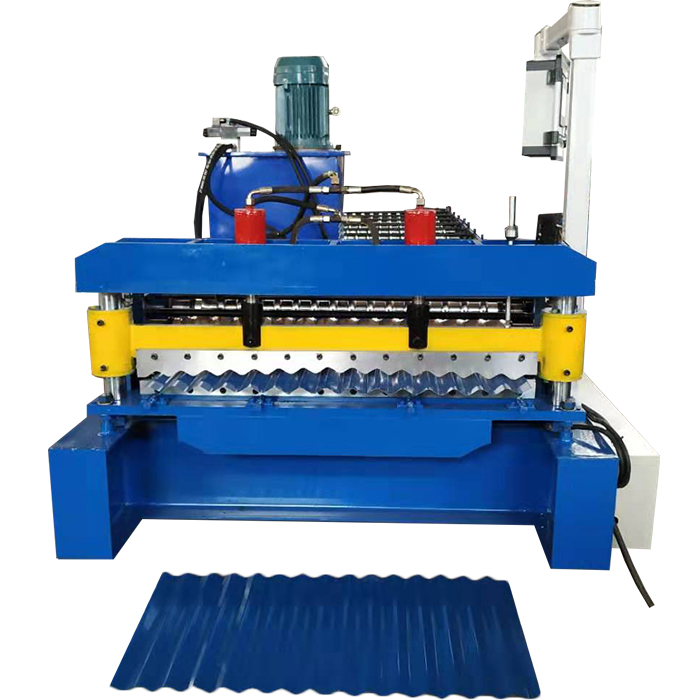

988 Corrugated roof roll forming machine details showing

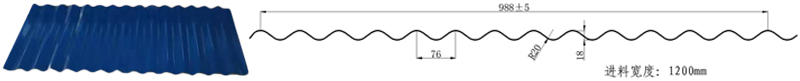

This machine can produce corrugated roof tiles. The final product is as follows:

Technical Parameters (some depend on the final design)

| Style | 988 Corrugated Roof Roll Forming Machine |

| Machine dimension | 6800*1450*1600mm |

| Total weight | 4500kgs |

| Forming steps | 13rows |

| Forming speed | 1.5-3.0m/min |

| Hydraulic station power | 4kw |

| Diameter of shaft | 70mm |

| Hydraulic pressure | 18-20 MPa |

| Electric condition | 380V/3Phase/50HZ |

| Suitable to process | Color steel plate(G300~G550 ) |

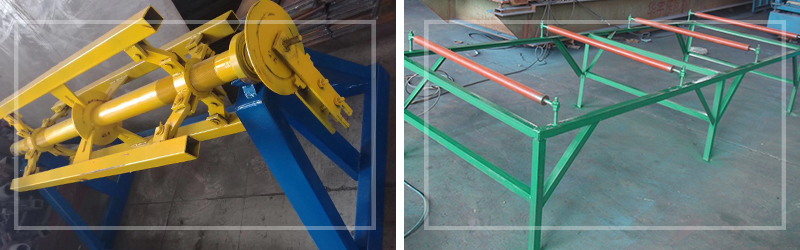

| Manual uncoiler max capacity | 5000kgs |

| Control system | PLC |

| Raw material thickness | 0.3-0.8mm |

| Effective width | 988mm |

| Material width | 1200mm |

| Main motor | 5.5Kw |

| Material of the cutting blade | Cr 12 quenched treatment 58℃-62℃ |

| Main Shaft Material | 45# steel with finish turning |

| Roller materials | 45# Forging Steel with Chromium Plate |

| Machine Under Frame | 350 H beams |

We offer our customers easy-broken parts for free.

Application

Roof roll forming machines mainly produce roofing, wall panels and door panels for building appliances and transportation. Corrugated roof sheet making machine can use galvanized steel, color steel plate or aluminum plate as material board.

Our Services

1. Installation and training:

a. If buyers visit our factory and check wave roof roll forming machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

c. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

2. After Service

a. Two years guarantee for the whole machine life.

b. 24 hours technical support by email or call.

c. If there is any problem found of the machine, we will repair it for free in one year.

FAQ

Q: How is this machine’s service life?

A: In the normal maintenance, the service life at least 8 years.

Q: Can you be responsible for transport?

A: Yes, please tell me the destination port or address. We have rich experience in transport.

Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q: How many workers operate this machine to manufacture?

A: Only 1-2 worker.

Q: Can you supply the raw materials?

A: Yes, we can supply the galvanized steel coil, galvalume steel coil, color steel coil, and aluminum coil.

Q: Why choose your company’s products?

A: Because of our products cost-effective, not only high quality and affordable.

Q: Does one machine can only produce one style panel profile?

A: Not exactly. For wider and double layer making machine. It can produce more than 3 kinds of panels.

Q: How long does it take to produce the machine?

A: Generally speaking, the machine can be completed within 20~45 working days. But if you need machines urgently, we can do our best to save you time.