By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for OEM Customized China Light Steel Angle Bar Wall Angle Steel Wall Angle Bar V Type Keel Roll Forming Machine, Welcomes all overseas friends and retailers to determine collaboration with us. We’ll offer you with truthful, premium quality and economical services to fulfill your needs.

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for China Angle Board Machine, Steel Bar Machine, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We are looking forward to establish business relation with you.

The cold-formed keel of t grid light steel keel roll forming machine is a kind of frame used to support the shape and fixed structure. The keel is the skeleton and substrate of the home decoration. It is very common to use and can be designed according to the buyer’s sample or drawings.

|

T grid light steel keel roll forming machine parameters |

||

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | As customer need |

| 3 | Thickness of the plate | 0.5-1.2mm |

| 4 | De-coiler | Manual one, can load 3 tons raw material |

| 5 | Rollers for forming | 18 rows |

| 6 | Diameter of the roller | Φ52mm |

| 7 | Rolling material | Carbon steel 45# |

| 8 | Main motor power | 4kW |

| 9 | Productivity | 8-12m/minute |

| 10 | Cutting method | Hydraulic mold cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kW |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 25mm |

| 16 | Main structure of the machine | 300H steel |

| 17 | Weight | About 6.5T |

| 18 | Dimensions | 5.5*1.0*1.5m |

| 19 | Voltage | 380V/50Hz/3 phases (changeable as needs) |

Components:

Manual decoiler ——————————————1 set

Guiding platform —————————————–1 set

Main machine of roll forming —————————1 set

Electric motor ———————————————1 set

Cutting device ———————————————1 set

Hydraulic station ——————————————1 set

PLC control ————————————————1 set

Supporter table ——————————————–1 set

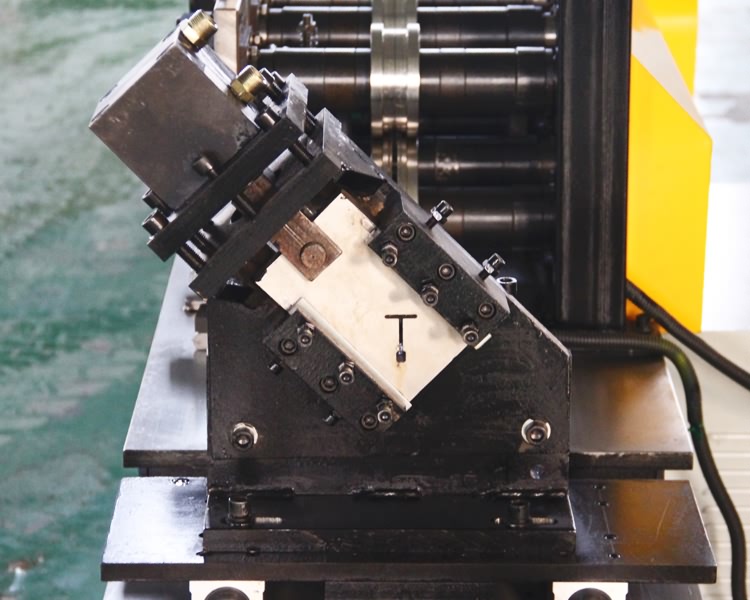

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Sales Service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad, we will arrange the technician, but the buyers should take all the cost, including visa, round trip ticket etc.

FAQ

Q: Is there quality control when manufacturing the lines?

A: Yes, we have a group of team who will be responsible for quality control from laying off the raw material, processing the rollers and the other parts, make treatment on the roller surface and shaft, assembling, testing and packaging.

Q: What’s your strength comparing to the other supplier?

A: We’ll supplying you the best quality and service. We’ll give you good advise beyond your requirements. The lines are easily for installation and with low maintenance requirements.