Persisting in “High quality, Prompt Delivery, Aggressive Price”, now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients’ large comments for OEM China Trapezoidal Sheet Roof Tile Roll Forming Machine For Production Line, should you’ve any query or wish to place an initial buy make sure you will not wait to get hold of us.

Persisting in “High quality, Prompt Delivery, Aggressive Price”, now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients’ large comments for Cold Roll Forming Machine / Roll Making Equipment, Roll Former / Roll Forming Machine, Trapezoidal Sheet Roof Tile Roll Forming Machine For Production Line, With the growing of the company, now our products sold and served at more than 15 countries around the world,such as Europe,North America,Middle-east,South America,Southern Asia and so on. As we bear in our mind that innovation is essential to our growth, new product development is constantly.Besides, Our flexible and efficient operation strategies,High quality products and competitive prices are exactly what our customers are looking for. Also a considerable service brings us good credit reputation.

|

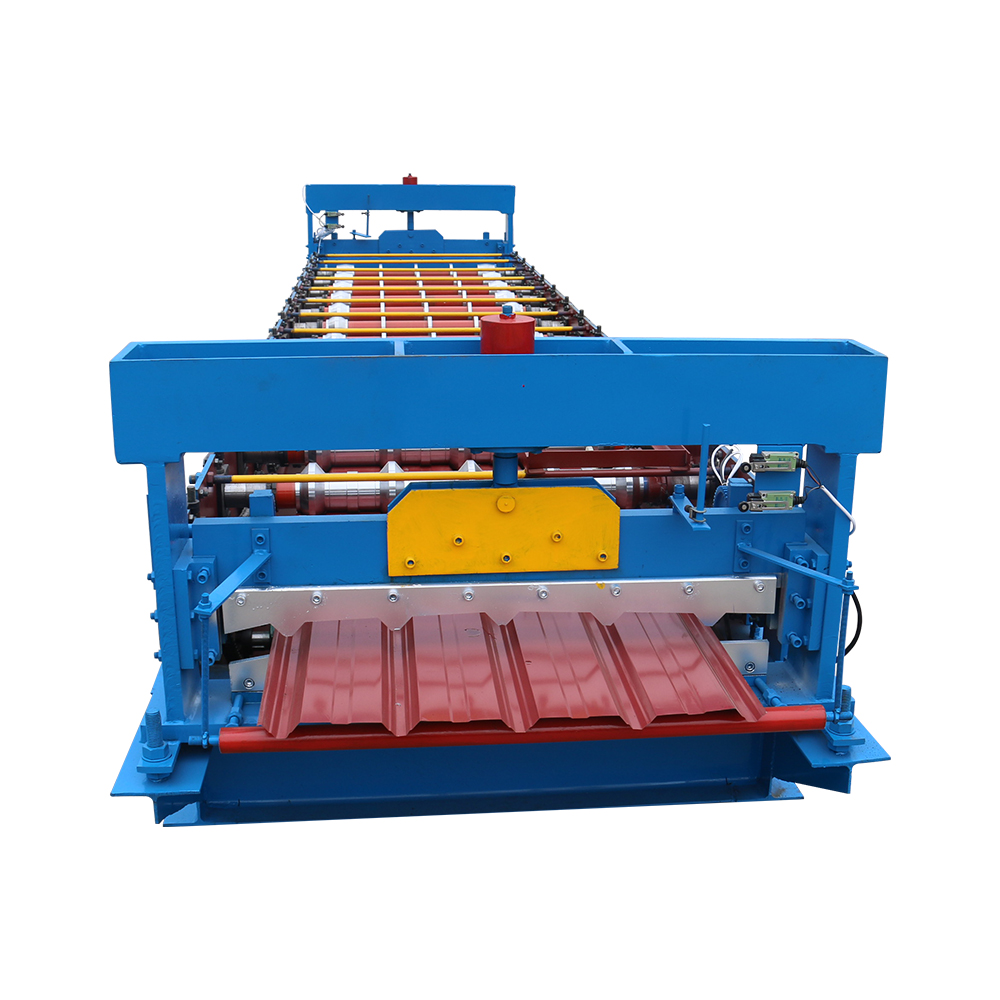

Trapezoidal roofing roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Choose our machine and save your money from every part!

a. Low labor cost;

b. Convenient transportation;

c. Complete supporting industries.

FAQ

Q: What’s your strength comparing to the other supplier?

A: We’ll supplying you the best quality and service. We’ll give you good advise beyond your requirements. The lines are easily for installation and with low maintenance requirements.

Q: Can we be your agency abroad?

A: Surely if you have business for roll forming lines and we will welcome a lot for cooperating together.

-

Factory Cheap Australian Style Hydraulic Cuttin...

-

OEM Supply Colored Color Coated Corrugated Stee...

-

Factory made hot-sale Carbon Steel Cnc Plasma C...

-

Good quality Double Layer Roof Panel Metal Roof...

-

Chinese wholesale Color Steel Galvanized Metal ...

-

Rapid Delivery for Widely Used Color Steel Meta...