Sticking to the perception of “Creating products of top of the range and earning mates with people today from all over the world”, we constantly put the desire of consumers in the first place for OEM China China Zinc Corrugated Roof Roll Forming Machines, We take quality as the foundation of our success. Thus, we focus on the manufacture of the best quality products. A strict quality management system has been created to ensure the quality of the products.

Sticking to the perception of “Creating products of top of the range and earning mates with people today from all over the world”, we constantly put the desire of consumers in the first place for China Roll Forming Machine, Cold Roll Forming Machine, Ensuring high product quality by choosing the best suppliers, we have now also implemented complete quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

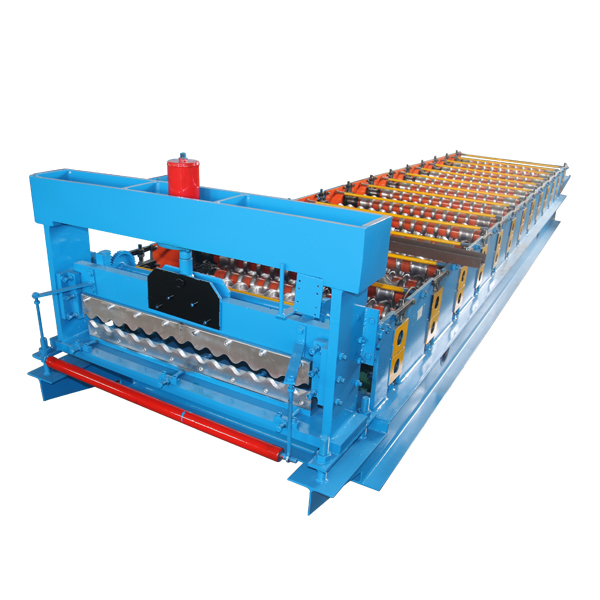

Parameters of corrugated metal roofing sheet machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Photos:

If you have any questions about the model, parameters, etc., please feel free to contact us. We will do our best to answer your questions and look forward to cooperation.