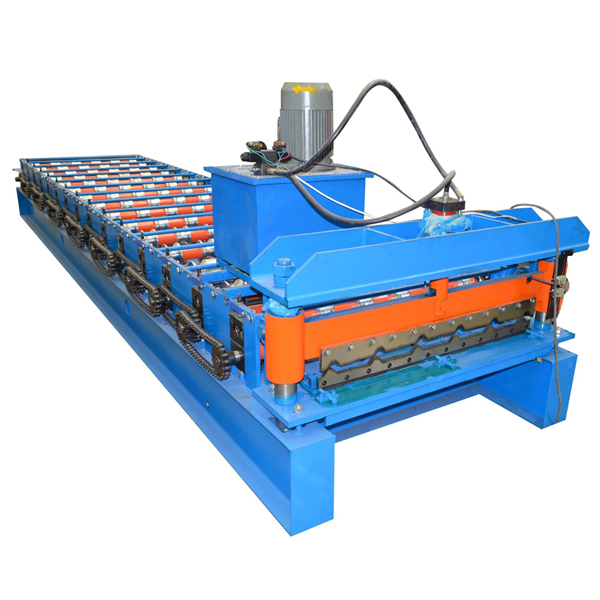

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for ODM Supplier Glazed And Trapezoidal Roofing Tile Profiles Double Layer Roll Forming Machine, Our experienced complex workforce might be wholeheartedly at your support. We sincerely welcome you to definitely stop by our web site and company and mail us your inquiry.

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Glazed Roofing Tile Forming Machine, Roofing Tile Profiles Double Layer Roll Forming Machine, Trapezoid Roof Tile Machine, Many years of work experience, we now have realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question issues they do not understand. We break down those people barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

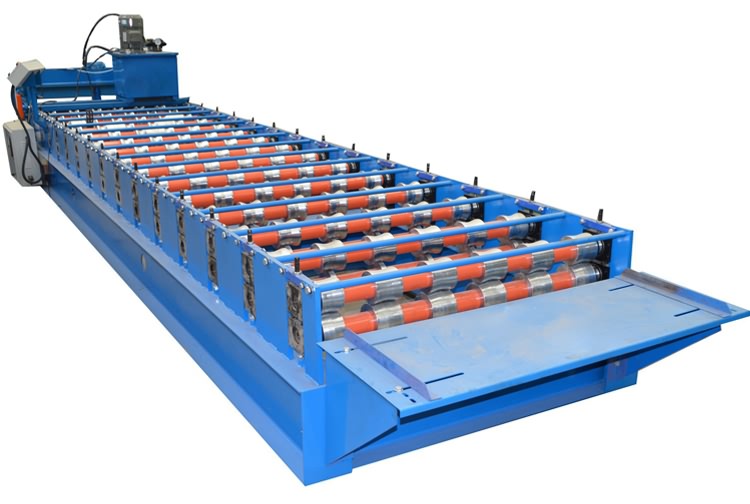

Aluminum trapezoidal roof making machine can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

|

Aluminum Trapezoidal Roof Making Machine Parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Detail of machine:

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).