Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for ODM Manufacturer Self Adhesive Tape Slitting Line Machine, We welcome you to definitely visit our manufacturing unit and stay up for creating pleasant small business interactions with consumers in the home and overseas inside the in the vicinity of long term.

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Gum Tape Slitting Machine, Self Adhesive Tape Slitting Machine, Tape Slitting Rewinding Machinery, Our company always provides good quality and reasonable price for our customers. In our efforts, we already have many shops in Guangzhou and our products have won praise from customers worldwide. Our mission has always been simple: To delight our customers with best quality hair solutions and deliver on time. Welcome new and old customers to contact us for the future long term business relationships.

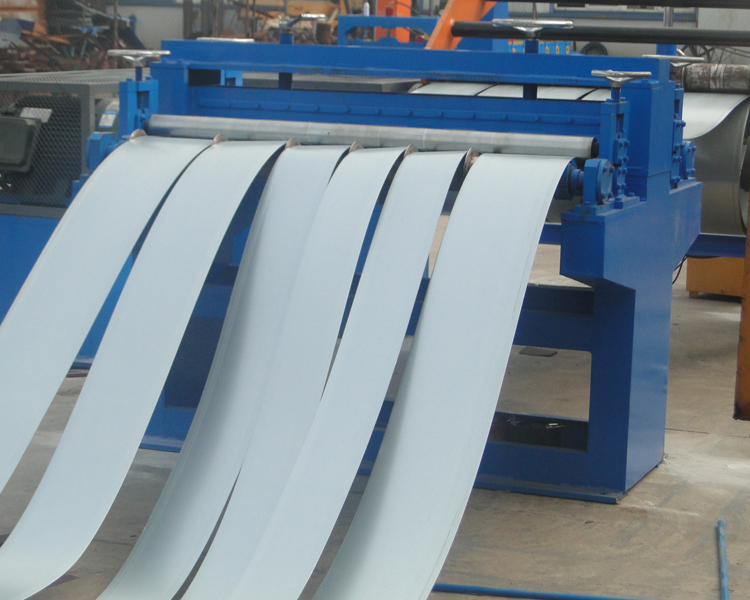

Slitting machine line cuts the metal coil into strips of various widths required, and then collects the strip into small rolls for use in the next process.

|

Slitting line machine parameters |

||

|

Raw Material (if the material is stainless steel, please tell in advance) |

1 | Material: carbon steel and others |

| 2 | The thickness of the material: 0.4mm-6mm. | |

| 3 | Width: 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm | |

| 4 | Input width: 600-1600mm | |

|

Hydraulic decoiler with car |

1 | The inner size: 450–610mm |

| 2 | The Max width: 1250mm | |

| 3 | The capacity: 15T 20Ton or more | |

|

Flatting and Cutting System |

1 | 2 shafts for feeding coil, 9 shafts for flatting |

| 2 | material of flatting: 42CrMo heat treated 50-52. | |

| 3 | hydraulic system. | |

| 4 | 2 sets cutting blade | |

| 5 | width of cutting: 600mm–1220mm. | |

| 6 | the material of blade mould: Gr12MoV | |

| 7 | power: 22KW Motor with ZQ650 Reducer | |

|

Slitting system |

1 | The width range: 200–1300mm |

| 2 | The precious of the width: ±1mm | |

| 3 | The speed of slitting: 25m/min | |

| 4 | The width can be change. | |

| 5 | Material of the slitting: Cr12MoV. | |

| 6 | Hardness of slitting blade: HRC5860. | |

| 7 | Slitting: 2~3mm 6 lines. | |

| 8 | Quantity of blades: 10 sets. | |

| 9 | Width of side scrap: 3-15mm | |

| 10 | The precious of side scrap: ±0.5mm | |

| 11 | Quantity of side scrap: 2 strips | |

| 12 | Power of the slitting: 37KW, 1000r/min, with ZQ750 Reducer. | |

|

Control System |

1 | Screen: 3.2inch button screen |

| 2 | PLC: Delta | |

|

Electrical collecting machine with car |

1 | Material inner: 550-650mm |

| 2 | Max Coil width: 1500mm | |

| 3 | Carrying capacity: 5T | |

| 4 | Automatic relax or collect | |

| 5 | Power: 22KW | |

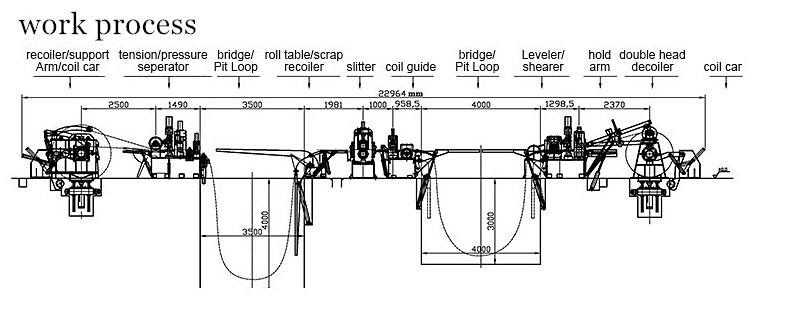

Working process

Decoiler —-flatting and cutting—slitting—–flatting and collecting

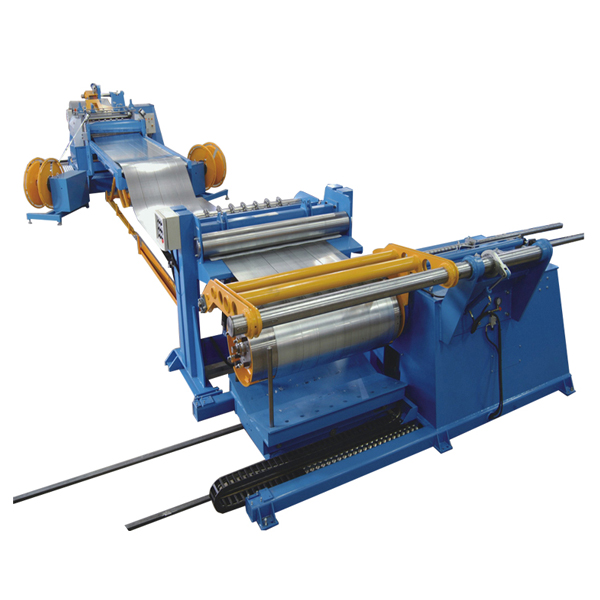

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

sheet slitting metal straightening steel coil s...

-

China New Product Roller Shutter Door Roll Form...

-

2019 Good Quality 10mm Automatic Cnc Hydraulic ...

-

Low price for Light Gauge Steel Framing Machine...

-

ODM Supplier Glazed And Trapezoidal Roofing Til...

-

Hot Sale Portable Metal Roofing Roll Forming Ma...