We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we’re much more specialist and extra hard-working and do it in cost-effective way for ODM Factory Roll Forming Machine Rollformers Metal Roofing Corrugated Steel Sheet Wall Panel Tile Making Machine, Adhering for the enterprise philosophy of ‘customer initially, forge ahead’, we sincerely welcome shoppers from in your house and abroad to cooperate with us.

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we’re much more specialist and extra hard-working and do it in cost-effective way for Metal Roof Panel Roll Forming Machine, Metal Roof Sheet Tile Making Machine, Roof Roll Forming Machine, We provide OEM services and replacement parts to meet the varying needs of our customers. We supply competitive price for quality items and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

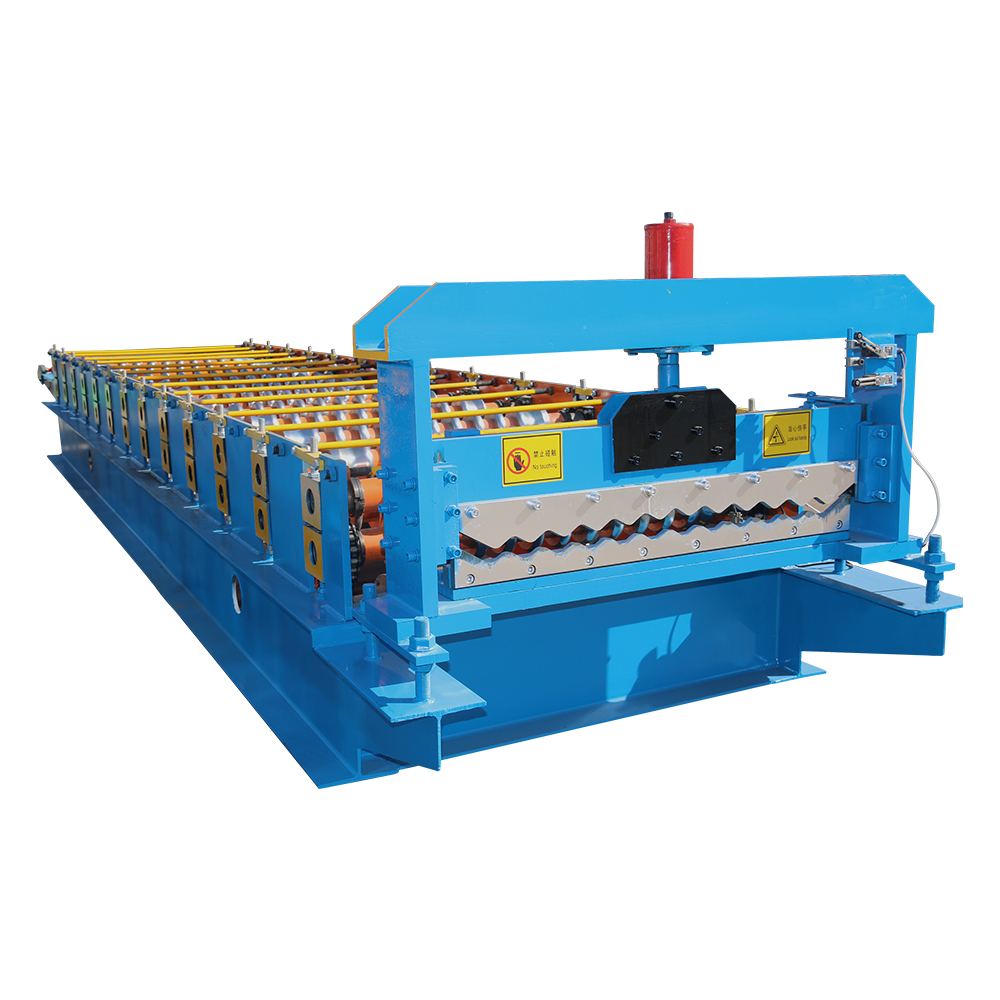

Parameters of corrugated sheet metal roofing roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Photos:

Sales Service:

1.We provide the technical support for whole life of our machines.

2.If buyers need the technician to go abroad, we will arrange the technician, but the buyers should take all the cost ,including visa, round trip ticket etc.

Company introduction details

Haixing Industrial Group Co., Ltd. is the biggest and strongest in north China. Our factory is specialized in manufacturing color steel forming machinery, C&Z purlin machine, glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine and other cold roll forming machines.

-

Personlized Products Innovative Roller Shutter ...

-

ODM Manufacturer C Purlin Roll Forming Machine,...

-

Top Suppliers Steel Deck Roll Forming Machine X...

-

Cheapest Factory High speed Automatic OPP BOPP ...

-

Factory Price For Make To Order Coiling Electri...

-

Top Grade Metal Floor Deck Sheet Roll Forming M...