Newly Arrival Shutter Door Machine - Curved Roof Panel Roll Forming Machine – Haixing Industrial Detail:

Application of Curved Roof Panel Roll Forming Machine

For architecture: making roof panel, wall panel, ceiling panel, etc.

For Industry: making refrigerating room panel, automobile panel, electric appliance housing, etc.

|

Curved Roof Panel Roll Forming Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

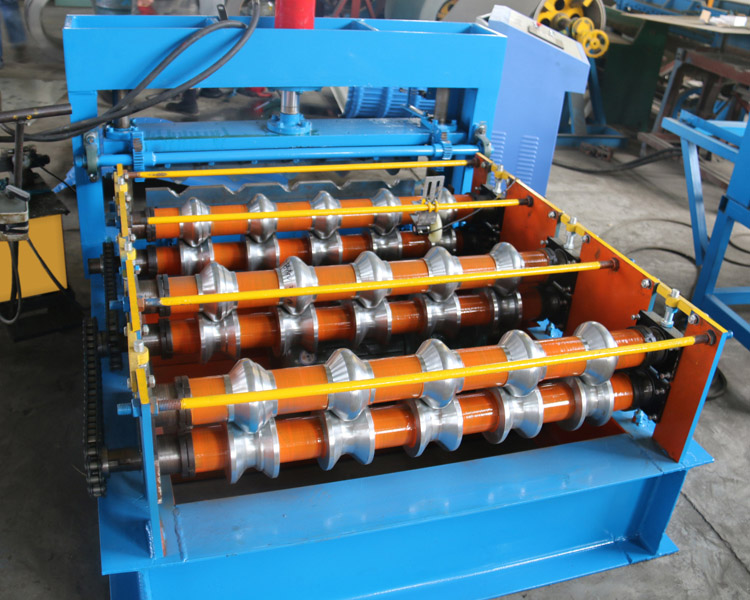

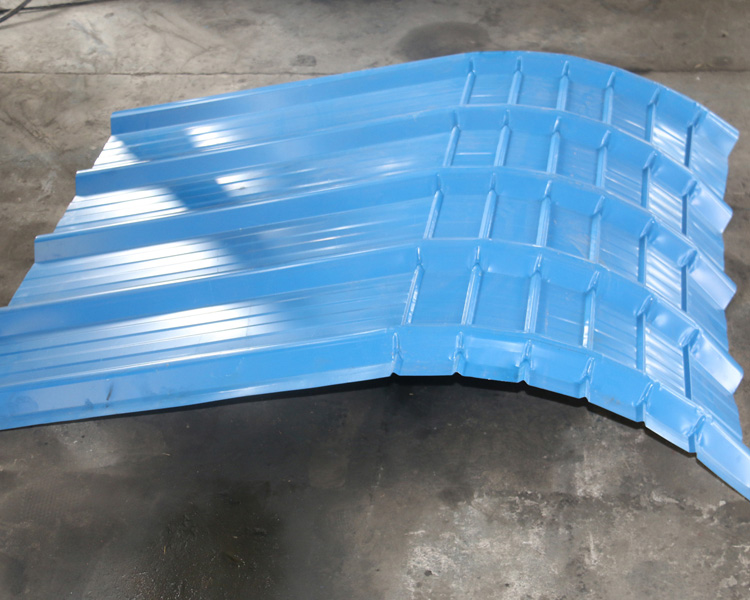

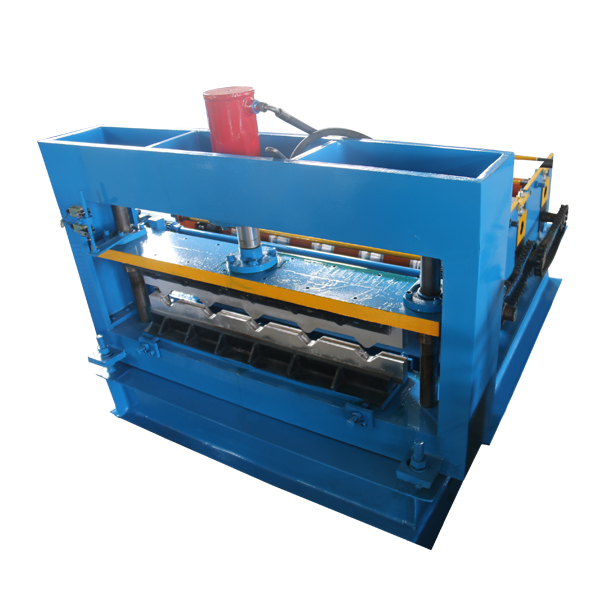

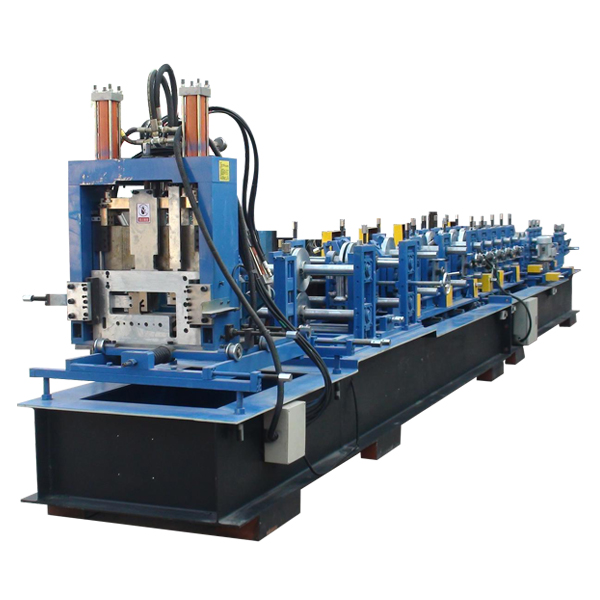

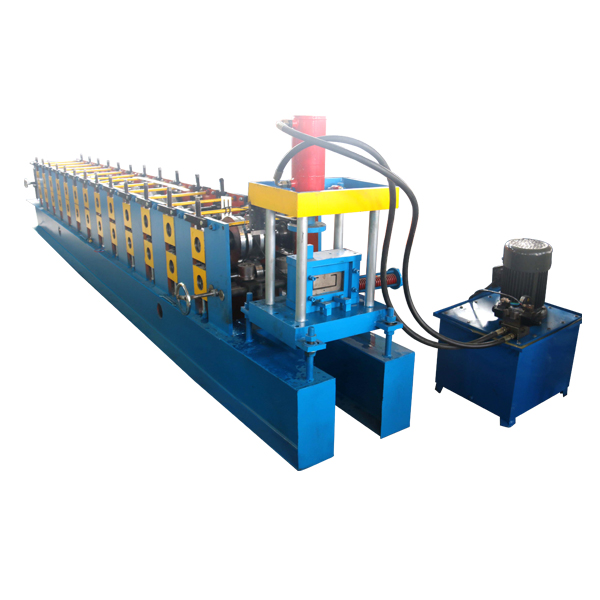

Machine Photos:

Package and shipment details:

1. Main roll forming machine package by plastic film

2. Main machine spare parts package by paper box

3. We have a professional technician load to ensure that the goods are loaded into the container without any damage.

4. Transportation: machines need one 20 feet container to hold.

5. Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Product detail pictures:

Related Product Guide:

Why Apple’s New HQ Is Nothing Like the Rest of Silicon Valley | Floor Deck Macking Machine

Five Classic Designs That Help Kids Become Independent | Decoiler In Color Coating Line

Newly Arrival Shutter Door Machine - Curved Roof Panel Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Wholesale Dealers of Corrugated Roll Machine -...

-

Fixed Competitive Price Roof Panel Roll Fomring...

-

China Factory for Slitting Machines - Trapezoi...

-

Top Suppliers Custom Design Floor Deck Forming ...

-

Newly Arrival Portable Solder Fume Extractor -...

-

Factory Cheap Steel Half Round Waterdown Gutter...