Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for Newly Arrival -end Low Roof Panel Ridge Cap Tile Machine, We sincerely look forward to hearing from you. Give us a chance to show you our professionalism and passion. We are sincerely welcome good friends from numerous circles at dwelling and abroad come to cooperate!

Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for -end Roof Panel Ridge Cap Tile Machine, Low Roof Panel Ridge Cap Tile Machine, Roof Panel Ridge Cap Tile Machine, When you are keen on any of our objects following you view our product list, please feel free to make contact with us for inquiries. You’ll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we have been able to. If it’s convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We’re generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

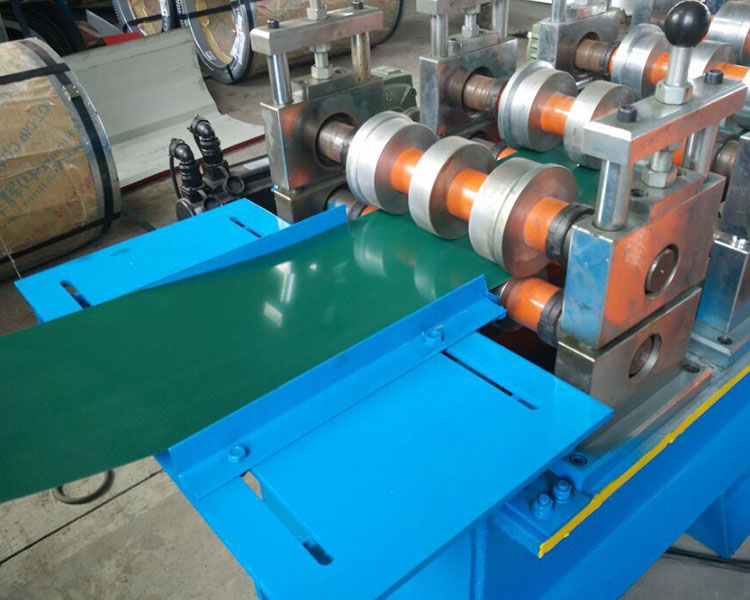

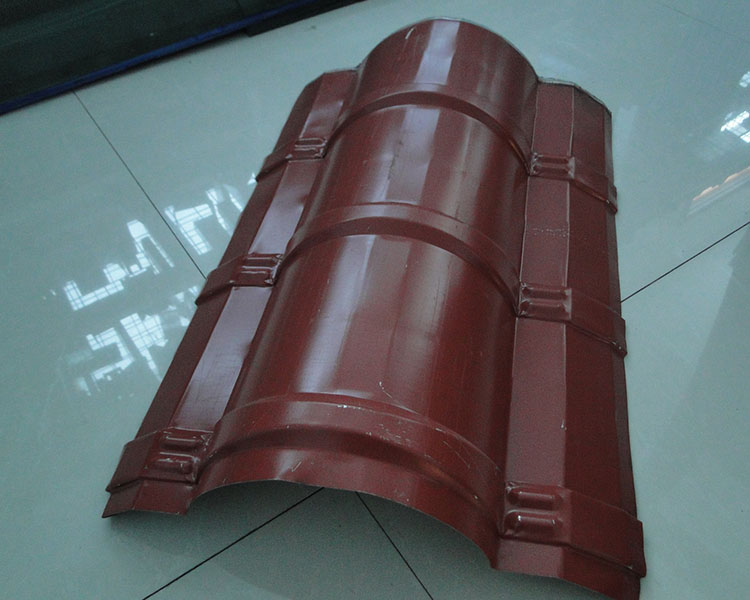

The galvanized ridge roofing sheet/cap roll forming machine is mainly used to produce the roof panel. The traditional ridges are made of glazed tiles, but have now been replaced by new ridge tiles. The color steel ridge tiles and aluminum-formed ridge tiles that are pressed out of roof ridge making machine are lighter, easier to install and less expensive.

|

Machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

Components of Galvanized Ridge Roofing Sheet/Cap Roll Forming Machine

1. Manual Decoiler…………………………………………….1 set

2. Feeding Guide……………………………………………….1 set

3. Main Roll Forming Machine……………………………1 set

4. Hydraulic Cutting Device………………………………..1 set

5. Hydraulic Station…………………………………………..1 set

6. PLC Computer Control…………………………………..1 set

7. Output Table…………………………………………………1 set

Machine details:

Package and shipment details:

The machines sold by Haixing Industrial Group Co., Ltd. use standard export packaging, as follows:

1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

-

2019 New Style Automatic Stud And Track Light K...

-

Factory best selling Galvanized C Frame Sheet M...

-

Renewable Design for Top Sale Speed Precision S...

-

Factory Customized Galvanized Steel Sheet Profi...

-

OEM/ODM Factory Aluminum Profile Bending Machin...

-

Best quality China ASA U-PVC Corrugated Roof Ti...