Our pursuit and company purpose is always to “Always satisfy our consumer requirements”. We keep on to acquire and style and design remarkable high-quality products for each our outdated and new customers and reach a win-win prospect for our consumers as well as us for New Delivery for Eco Friendly Grade No.45 Forged Color Steel Stone Coated Roof Tile Making Roll Forming Machines, Are you still looking for a quality product that is in accordance with your good company image while expanding your product range? Try our quality products. Your choice will prove to be intelligent!

Our pursuit and company purpose is always to “Always satisfy our consumer requirements”. We keep on to acquire and style and design remarkable high-quality products for each our outdated and new customers and reach a win-win prospect for our consumers as well as us for Color Steel Stone Coated Roof Tile Making Machinery, Color Stone Coated Tile Roll Forming Machine, Stone Coated Roll Forming Machines, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

Our Steel Colored Stone Coated Production Line meets the diverse requirements of our customers.

The Steel Colored Stone Coated Production Line is described in detail as follows:

NO. 1 Auto bottom glue spraying section

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements) |

| Automatic pressure spray tank | 1set; Capability:200kg; Range:0.6~1Mpa |

| Automatic glue machine motor | Servo motor; Power:750w; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set; Power: 200w |

| Damp proof lamp | 1 pcs; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set; Power: 7.5kw |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Agitator | 1 set; Power: 1.5kw |

NO. 2 Auto stone coated section

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

NO. 3 The first time drying section

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

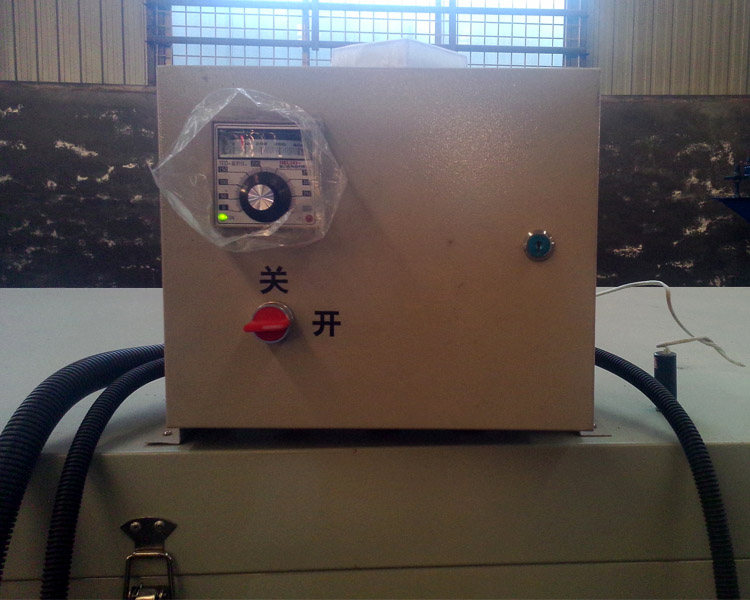

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

NO. 4 Auto face glue spraying section

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pcs; Power:100w |

| Automatic pressure spray tank | 1 set; Capability: 200kg; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Automatic glue machine motor | Servo motor; Power: 750w |

NO. 5 The second time drying section

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

Machine Photos:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.