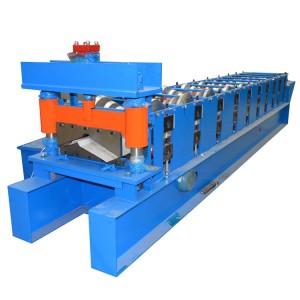

Metal Ridge Cap Roll Forming Machine for house construction

|

Machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

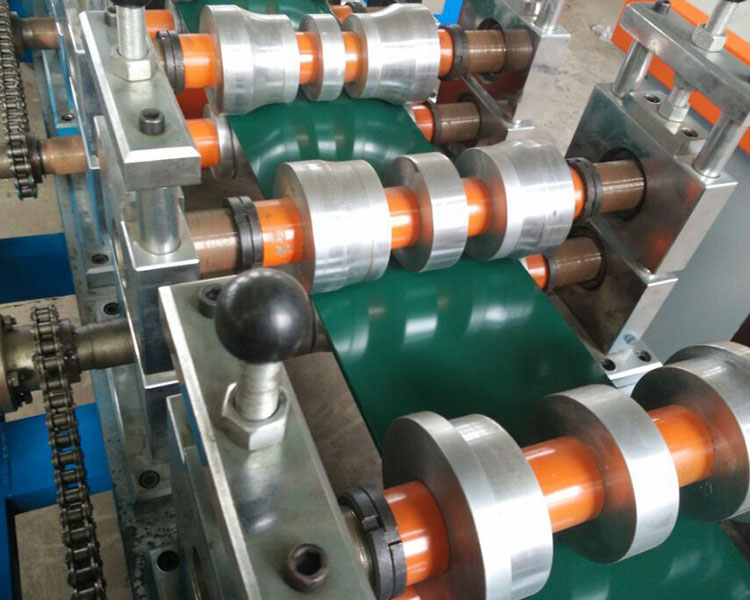

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

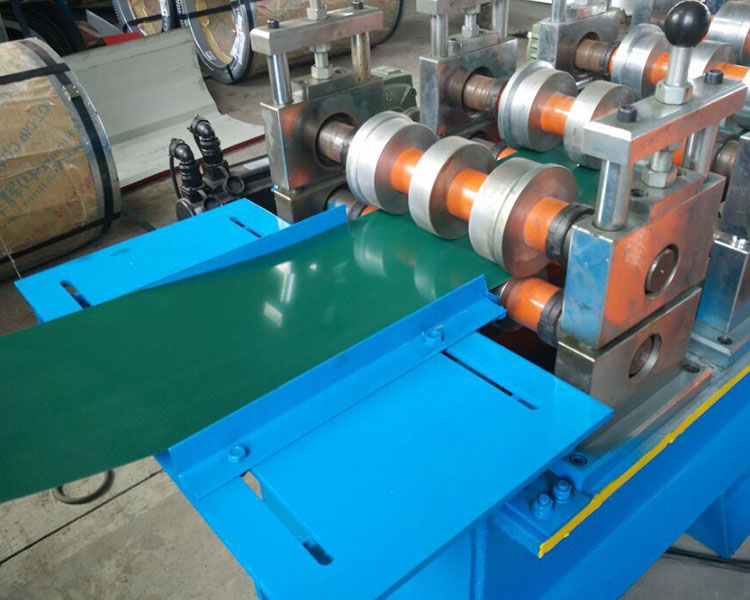

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

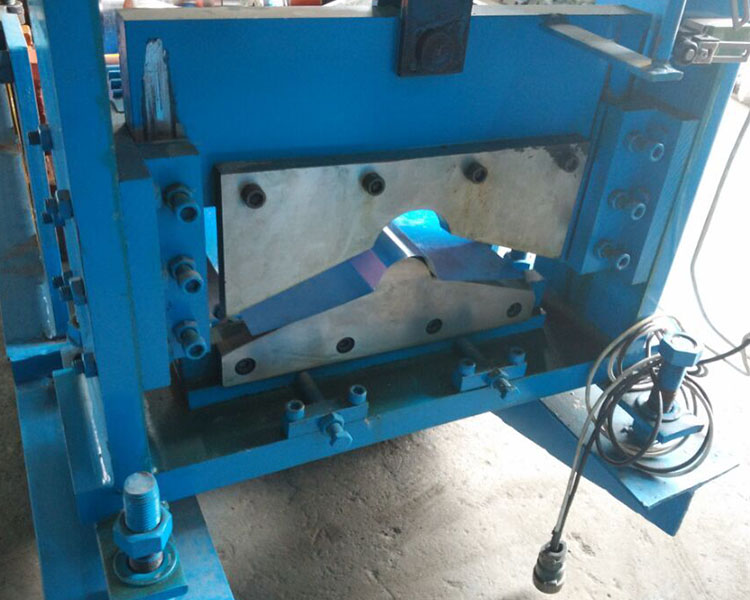

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta |

Why choose us?

Our company has a professional team of engineers and export team.

Engineer: 25; Factory workers: 88;

Finance staff: 2; Purchasing staff: 12;

Operator: 3; Sales staff: 8;

After-sales staff: 5.

Our machine is warranted for 24 months.

During the warranty period, if the damaged part cannot be repaired, we can send the new part for replacement of the damaged part for free, but you will need to pay the courier fee yourself. If after the warranty period, we can negotiate to resolve the issue and provide technical support throughout the life of the device.

We offer technical support for the entire life of our machines.

We can send our technicians to install and train the workers in the clients' factories.

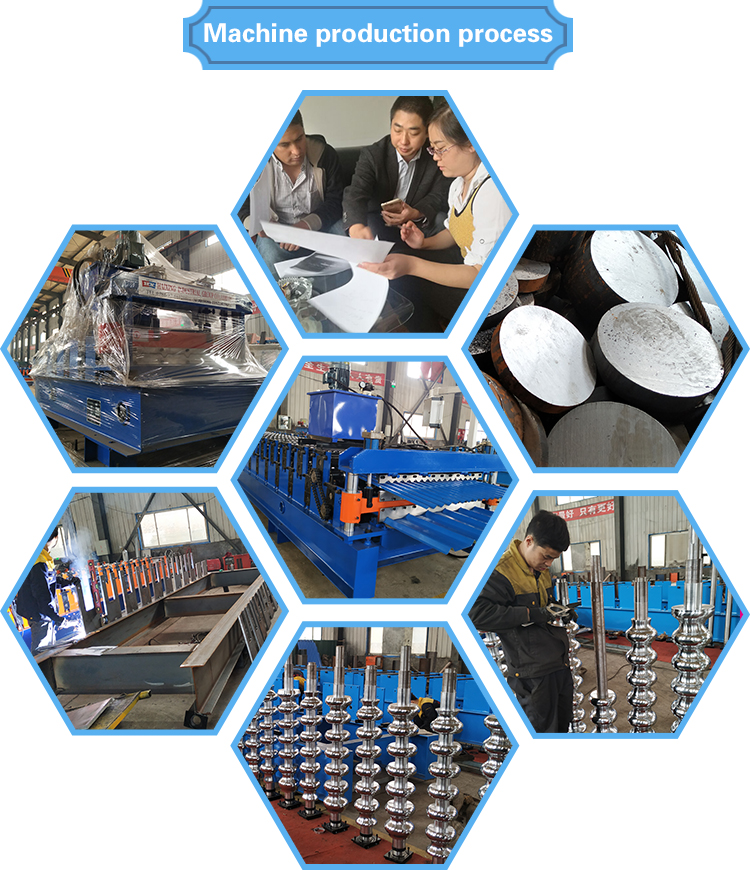

Drawing confirmation

——After confirming the final profile with the customer, the team of 12 engineers worked out detail workable parts CAD drawings;

——After 5 recheck, the production manager arrangement the material for all machine parts;

Start production

——Our company owns 12sets rough lathe machine, 20sets precise lathe machine, and 30sets shearing machine, all machine parts start to manufacture.

Product Inspection

——Our company Own 3sets hard test machine, and 4sets surface thickness Chromium test machine.

——Roller and shaft: Our Inspect team test 90% wheels and shafts, confirm all parts size precise and performance after processing.

——Our Inspect team test all roller surface, confirm all part surface paint above 5um.

——Mainframe and medium plate: Our Inspect team test the mainframe and plate cutting precise.

Assembling machine

——5 worker assemble and welding one machine body frame by three days.

Machine painting

——Putty ensure weld parts surface smoothly, and environment-friendly paint ensure protect worker body and environment.

Machine Manual use test

——Confirm the output sheet tolerance within 2mm.

Cutter production

——According to the finally manufacture sheet, confirm the blade precise profile, Cr12MOV steel cutting knife finished by laser cutting.

Storage

——To protect the machine surface clear and without damage, we paint again and package by the film.

Packaging

Our products are usually available in two packaging methods: plastic film packaging and plastic film + wooden box packaging.

1. The main machine is covered with plastic film.

2. PLC control box, spare parts, and other small parts are packed by wooden cartons.

Delivery

Two days before delivery, we unpacked and repainted the machine and repackaged it.

1) Q: Do you have after-sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3) Q: How does your factory do regarding quality control?

A: Quality is the priority. we always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers’ specifications, using top brand name components.

5) Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

-

C Light Steel Keel Roll Forming Machines

-

1000 Trapezoidal Metal Sheet Roll Forming Machine

-

1100mm steel tile roofing sheet roll forming ma...

-

5t/6t/7t/8t/10t/12t/15t/20t hydraulic decoiler ...

-

6m Steel Bending Machine

-

762 Corrugated Roof Metal Sheet Roll Forming Ma...

-

Advanced Cnc Hydraulic Metal Sheet Shearing Mac...