Massive Selection for Downspout Tube Pipe Machinery - Good quality Steel Door Frame Roll Forming Machine – Haixing Industrial Detail:

We usually believe that one’s character decides products’ high quality, the details decides products’ excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Good quality Steel Door Frame Roll Forming Machine, Welcome to contact us in case you are intrigued within our products, we’ll give you a surprice for Qulity and Cost.

We usually believe that one’s character decides products’ high quality, the details decides products’ excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Cold Roll Forming Machine, Steel Door Frame Making Machines, With the first-class products and solutions, excellent service, fast delivery and the best price, we have now won highly praise foreign customers’. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

|

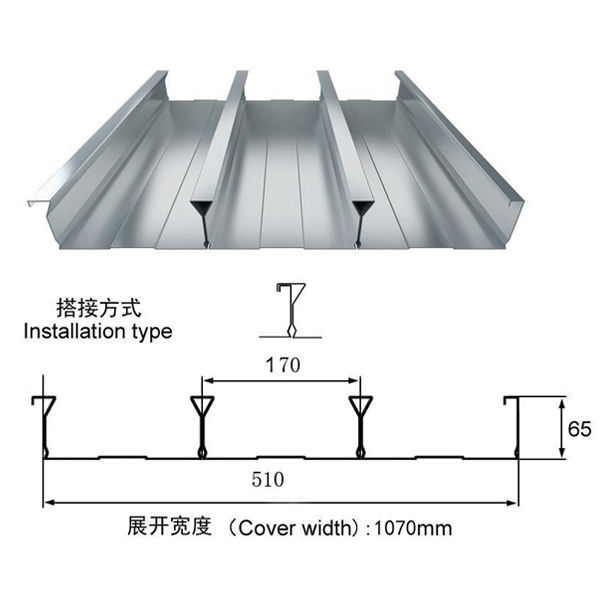

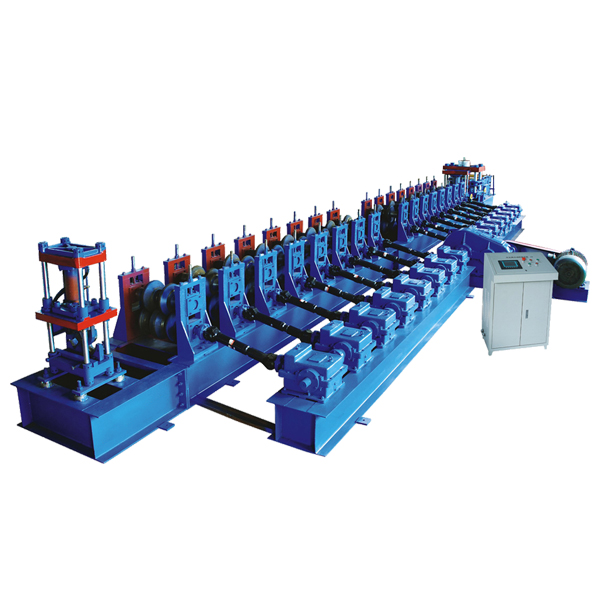

Steel profile door frame roll forming machine parameters |

||

| 1 | Material width | 3 sizes. Waiting for buyer exactly profile |

| 2 | How to adjust size | Option : by PLC (It can be adjust by PLC and also in hand wheel) One side fixed and the other is adjustable by manual or PLC |

| 3 | Base frame | base frame 30 mm thick steel plate process the surface on CNC planer to keep it leveling and drill bolts and key slot by CNC |

| 4 | Rolling Speed | 12-15m/min(not include cutting time) |

| 5 | Rolling Thickness | 1.2-2.0mm |

| 6 | Material | GI or metal |

| 7 | Control System | PLC (Panasonic) as list in the note |

| 8 | decoiler | 3 Ton manual decoiler |

| 9 | Leveling | Up in 3 roller, down in 4 roller |

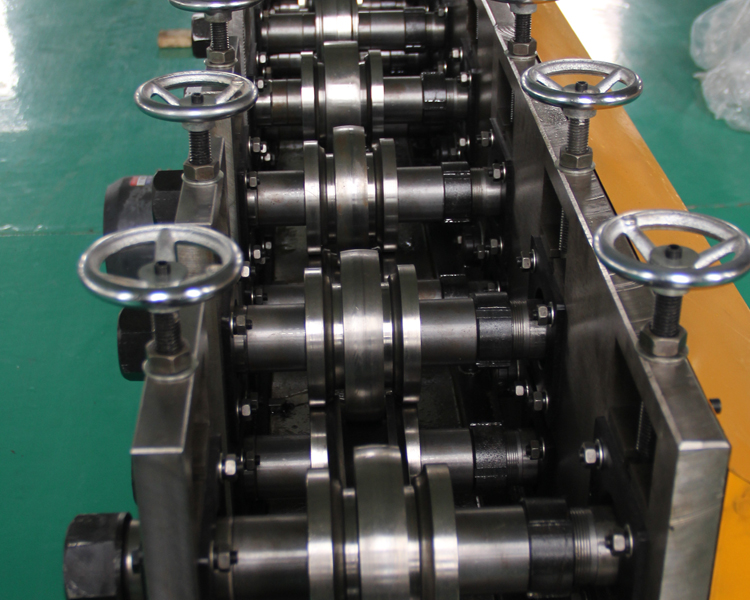

| 10 | Roller Stations | About 20 stations |

| 11 | Roller Material | Gcr15, coated with chrome HRC58-62 degree |

| 12 | Shaft Material and DIA | ¢70mm, material is 45# forge steel |

| 13 | Maim Motor Power | 11kw brake motor |

| 14 | Hydraulic Station Power | 5.5kw |

| 15 | Hydraulic Pressure | 20Mpa |

| 16 | Capacity of tonnage for punching | 22Tons |

| 17 | Hydraulic pump brand | Lichao |

| 18 | Cutting | Hydraulic post-cutting for cut end product |

| 19 | Extra cutter | One more cutter for each profile |

| 20 | Material Of Cutting | Cr12Mov quenching 58-62ºC |

| 21 | Electric Source | 380V, 60HZ,3 phase |

| 22 | Way Of Drive | 1.2 inch single chain |

| 23 | Color Of The Machine | Yellow and blue |

| 24 | Machine Type | Iron Cast |

| 25 | Emergency switch | In main machine and control panel all have emergency switch for forbid any urgently accident. |

| 26 | Protect cover | Complete mobile safety cover from roll forming to the cutter. |

| 27 | Size of the machine | L*W*H 12m*1.2m*1.2m |

| 28 | Container Need | 1 x40 feet (base on final) |

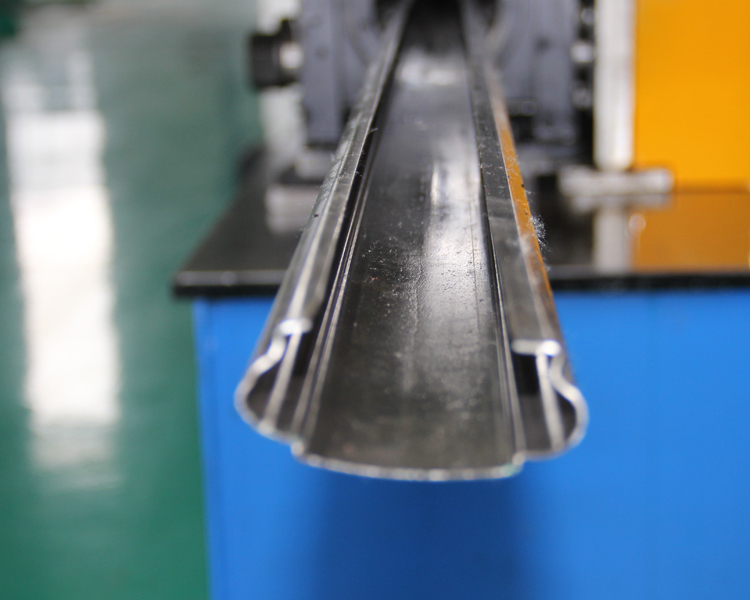

The steel door frame roll forming machine is a complete product line. After roll forming by our production line, we could make very smooth and beautiful steel door frame without any scratch on surface.

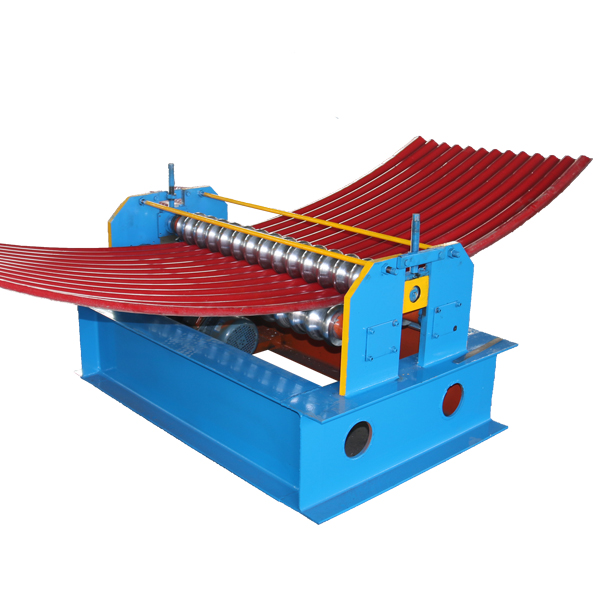

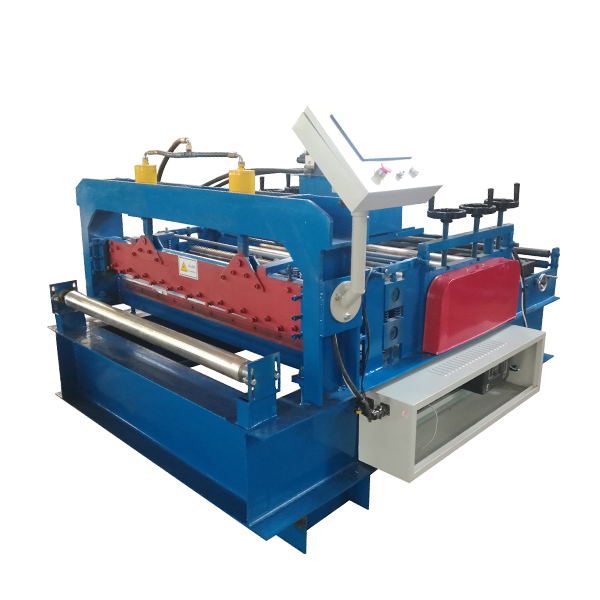

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

A Washing Machine with an Elevated Design | Steel Downpipe Roll Forming Machine

The tower challenge: Critics rate the view, food and drinks at Seattle tourist favorites Columbia Center, the Space Needle and Smith Tower | Ibr Roof Sheet Making Machine

Massive Selection for Downspout Tube Pipe Machinery - Good quality Steel Door Frame Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Bottom price Automatic Decoiler - T grid roll ...

-

Factory Free sample Decoiler In Color Coating L...

-

Factory directly supply U Profile Guide Rail Ro...

-

Popular Design for Smoke Fume Extractor - Galv...

-

Rapid Delivery for Purlin Angle Machine - Shee...

-

Super Purchasing for Coil Shearing Machine - M...