We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Manufacturer for Galvanized Steel Ridge Cap Tile Cold Roll Forming Machine, We wholeheartedly welcome shoppers all around the globe come to go to our manufacturing facility and have a win-win cooperation with us!

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Galvanized Steel Ridge Cap Tile Cold Roll Forming Machine, With high quality, reasonable price, on-time delivery and customized & personalized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

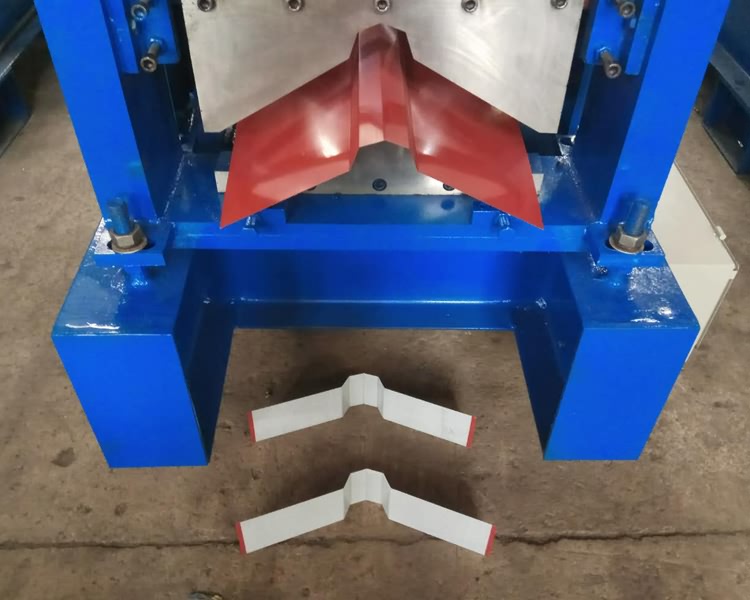

We can manufacture and design various color steel ridge cap roll forming machines according to customer requirements.

|

Color Steel Ridge Cap roll Forming Machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

Machine details:

Contact details

If you have any needs or questions, please feel free to contact us. We will be waiting for you here 24 hours. Please join us.

-

China New Product Galvanized C Bracket C Purlin...

-

China New Product 2017 New Arriving Steel Door ...

-

Factory directly 2018 Metal Roofing Glazed Tile...

-

China Gold Supplier for China Roof Corrugated S...

-

High Quality for 300*300 400*400 500*500 600*60...

-

Wholesale Automatic Roll Formers Corrugated Ste...