We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with Manufacturer for Galvanized Roofing Sheet Roll Forming Machine, Our goods are widely recognized and trusted by users and can satisfy continuously establishing economic and social needs.

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with Roll Former, Roof Panel Roll Forming Machine, Roof Tile Roll Forming Machine, To win customers’ confidence, Best Source has set up a strong sales and after-sales team to supply the best product and service. Best Source abides by the idea of “Grow with customer” and philosophy of “Customer-oriented” to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let’s grow together!

We have a variety of machinery and production methods to meet the growing needs of our customers. Our different types of roll forming operations are simple and efficient.

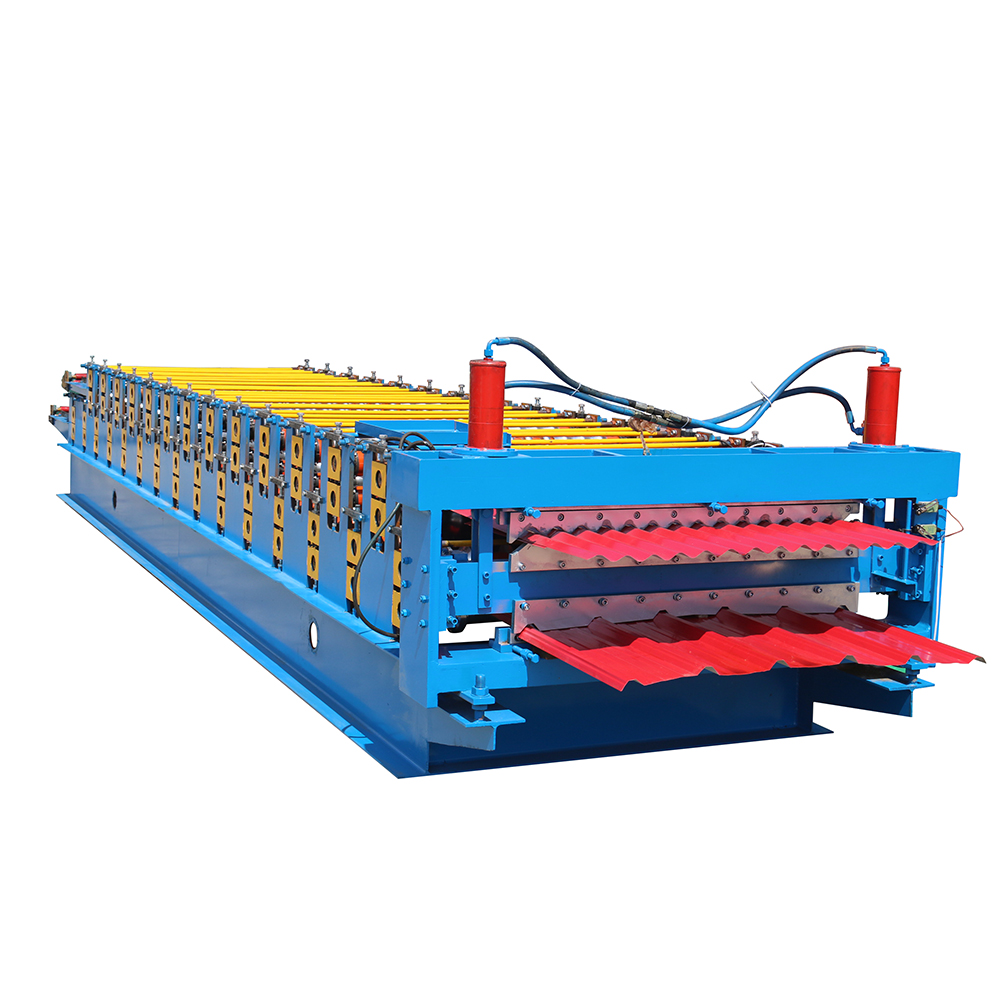

Parameters of double layer corrugated roof sheet making machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Machine photos

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our machine’s packaging:

1.Main roll forming machine package by Plastic film;

2.Main machine spare parts package by paper box;

3.We have professional technicians for loading, guaranteed the goods load into container without any damage.

-

China Wholesale Roller Shutter Door Profile Rol...

-

ODM Factory Made In Lead Wire Cutting Machine C...

-

High Quality for Similar As Samco Greenfield St...

-

Renewable Design for Judu Cnc Sheet Metal Bendi...

-

OEM/ODM Supplier Fashionable Patterns Plate Cor...

-

Factory best selling Aluminum Roof Tile Sheet P...