We try for excellence, company the customers”, hopes to be the best cooperation workforce and dominator enterprise for personnel, suppliers and clients, realizes value share and steady marketing for Manufactur standard s Making Building Material Wall Panel Metal Roofing Corrugated Tile Roll Forming Machine For Sale, We will do our best to satisfy your prerequisites and are sincerely on the lookout forward to acquiring mutual effective enterprise marriage with you!

We try for excellence, company the customers”, hopes to be the best cooperation workforce and dominator enterprise for personnel, suppliers and clients, realizes value share and steady marketing for Corrugated Roll Forming Machine, Metal Panel Roofing Making Machine, Tile Roll Forming Machine, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional solutions and vast knowledge of technology makes us the preferred choice for our customers.

The tiles pressed out by the glazed roofing tile roll forming machine are very beautiful, and the technical parameters of the machine are as follows:

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

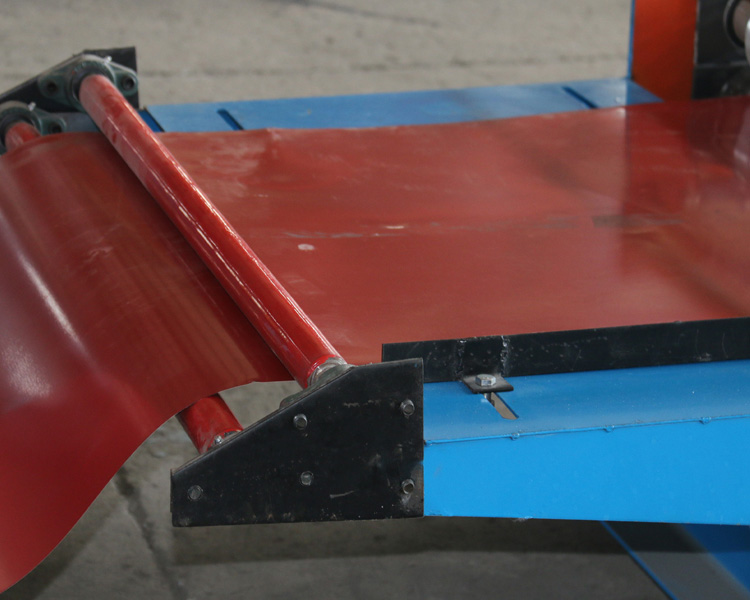

Glazed roofing tile roll forming machine components include: Manual un-coiler, Guiding platform, Coil strip leveler, Main machine of roll forming, Electric-motor, Cutting device, Hydraulic station, PLC control and Supporter table.

Machine Details:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Short Lead Time for Automatic Steel Sheet Slitt...

-

High Quality Automatic Metal Strips Channel Ben...

-

ODM Factory 5tons Hydraulic Decoiler With Coil Car

-

China New Product Corrugated Asos Cement Sheet ...

-

Hot Sale for Hot Sales 1000 Metal Sheet Trapezo...

-

Discount Price China Full Automatic Adjustable ...