Low price for Drywall Metal Studs And Tracks Machine - Short Lead Time for Omega Profile Roll Forming Machine C U Purlin Channel Truss Furring Cold Forming Machine – Haixing Industrial Detail:

We believe in: Innovation is our soul and spirit. Top quality is our life. Consumer will need is our God for Short Lead Time for Omega Profile Roll Forming Machine C U Purlin Channel Truss Furring Cold Forming Machine, We guaranteed high-quality, if clients were not pleased together with the products’ good quality, you can return inside of 7days with their original states.

We believe in: Innovation is our soul and spirit. Top quality is our life. Consumer will need is our God for Omega Channel Machine, Omega Machine, Omega Purlin Machine, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

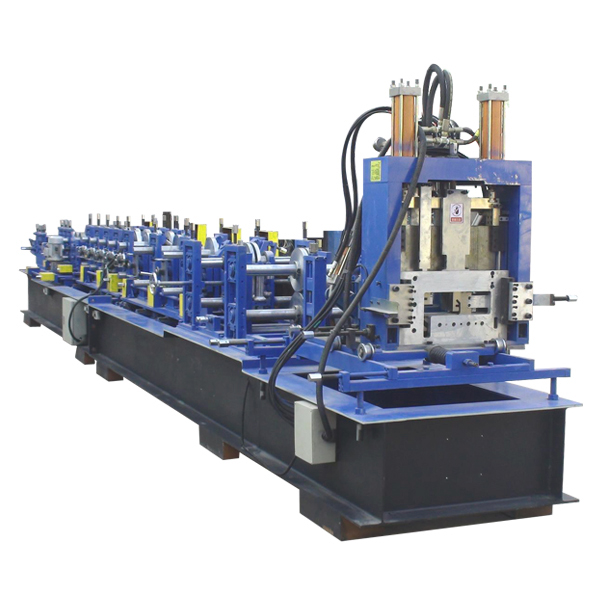

Automatic CZ interchange purlin machine process flow:

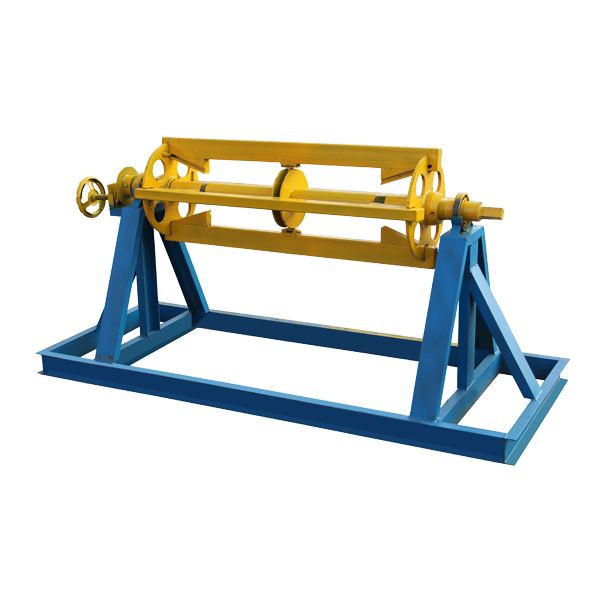

Manual decoiler– punching hole– roll forming machine– molding press– PLC control box– hydraulic system– post cut– output table.

|

Purlin roll forming machine |

||

| 1 | Suitable to process | Steel plate |

| 2 | Rollers | 18 rows(Before and after the leveling and contains no lead to send passes) |

| 3 | Dimensions | 11*1.3*1.5m |

| 4 | Power | 11.5kw+7.5kw |

| 5 | Thickness of the plate | 1-3mm |

| 6 | Productivity | 8-10m/min |

| 7 | Middle plate thickness | 20mm |

| 8 | Driving ways | 2.6-inch China wheels and link chain |

| 9 | Diameter and material of the forming axis | 80mm |

| 10 | Weight | About 8.5T |

| 11 | Voltage | 380V 50HZ3 phase |

| 12 | Roll material | GCr15(bearing steel)hard chrome plated after heat treatment |

| 13 | Shaft material | 40Cr Modulation of heat treatment after polishing hard chromium plating |

| 14 | On both sides of the wall material | A3 steel |

| 15 | Frame | International H-beam |

| 16 | Blade material | Cr12Mov |

| 17 | Forming wheel | Bearing steel quenching |

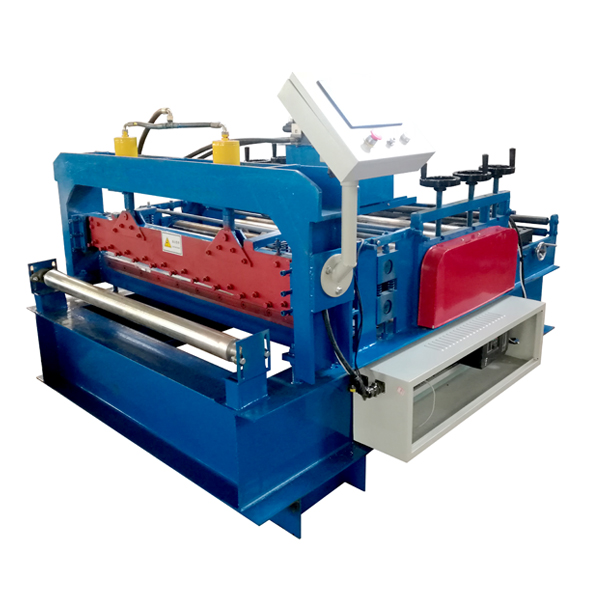

The machine comprises the following parts:

Single-end feeding machine(max capacity 5T), Feeding leveling, Forming system, Straightening mechanism(one word original), At single + double holes, After forming shear system, Supporting material platform(6m)

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit

2. Package: export standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after inspect the machine before delivery)

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.

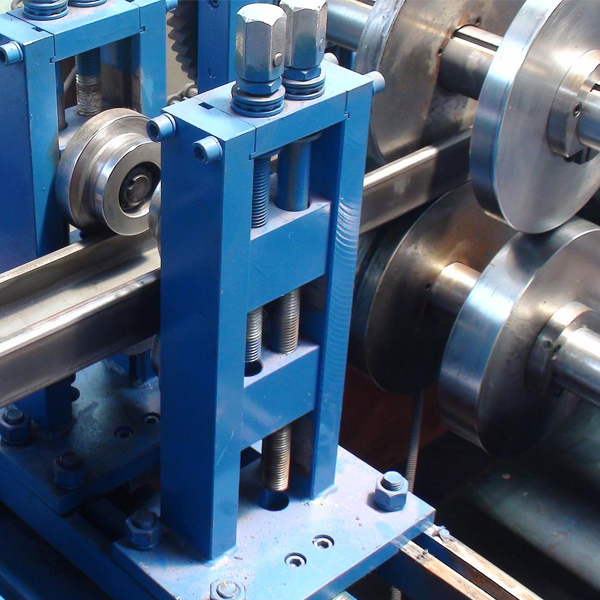

Product detail pictures:

Related Product Guide:

‘She makes children of us all’: Guardian writers pick their favourite Kate Bush lyrics | Music | Ibr Roof Sheet Making Machine

Symphony of the Seas: Giant Royal Caribbean cruise ship arrives in USA | Floor Deck Macking Machine

Low price for Drywall Metal Studs And Tracks Machine - Short Lead Time for Omega Profile Roll Forming Machine C U Purlin Channel Truss Furring Cold Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

China Supplier Corrugated Sheets Making Machine...

-

Hot Selling for Roof Making Machine - Roof rid...

-

OEM Customized Door Frame Steel Sheet Making Ma...

-

Cheapest Factory U Purlin Machine - Steel Colo...

-

Good Wholesale Vendors Light Steel Keel Ceiling...

-

Rapid Delivery for Hydraulic Curving Roof Formi...