We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our administration ideal for Low MOQ for China Hot Sale Ceiling T Bar Roof Panel Steel Stud and Track Roll Forming Machine, We promise to try our greatest to deliver you with high quality and economical products and services.

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our administration ideal for China Roll Forming Machine, Forming Machine, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products and solutions to customers at low cots, we’ve been committed to improving its capacities in research, development, manufacturing and management. We’ve honored to receive recognition from our customers. Till now we’ve got passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of “quality of survival, the credibility of development” for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

r panel roll forming roof tile press machine’s technical parameters

| Length of the main part | About10500*1650*1500mm |

| Weight of main part | About 9.5 tons |

| Voltage | 380V/50HZ/3Phase (as customer’s request) |

| Roller fixer | Middle plate welded |

| Frame | 350H steel welded |

| Middle plate thickness | 18mm |

| Drive mode | Chain Drice |

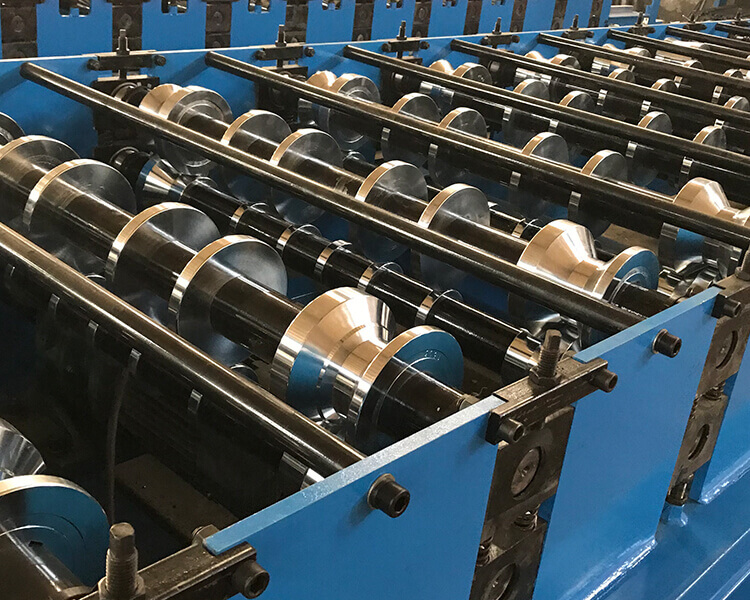

| Material of rollers | 45# steel, surface hard chromium plating. |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80mm(depend on different design) |

| Number of rollers: | 29 rollers |

| Main power | 5.5kw |

| Cutting&Hydraulic | Double guide pillar |

| Hydraulic motor power | 3kw,4kw |

| Hydraulic Pressure | 10-12MPa |

| Cutting drive | Decelerating motor + Chain drive gear all by high-frequency |

| Control System | PLC system: Mitsubishi, Panasonic,Dental,Siemens,Schneider |

| Feeding Material width | Better as your drawing or from our designer |

| Feeding Thickness | 0.8~1.5mm |

| Effective width | Better as your drawing or from our designer |

| Productivity | 8-12/min |

| Package of machine | Waterproofing membrane, standard export packing |

r panel roll forming roof tile press machine’s introduction and feature

1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer’s requests.

Equipment placement:

The base surface of all equipment should be horizontal and hardened. The decoiler, roll forming machine ,center line of the discharge rack, molding machine and discharge table should be on the same straight line, and the left and right sides should not be inclined. The distance between the discharge rack and the forming host should be ≥3m. After the equipment is placed in a stable position, it should be fixed with anchor bolts.