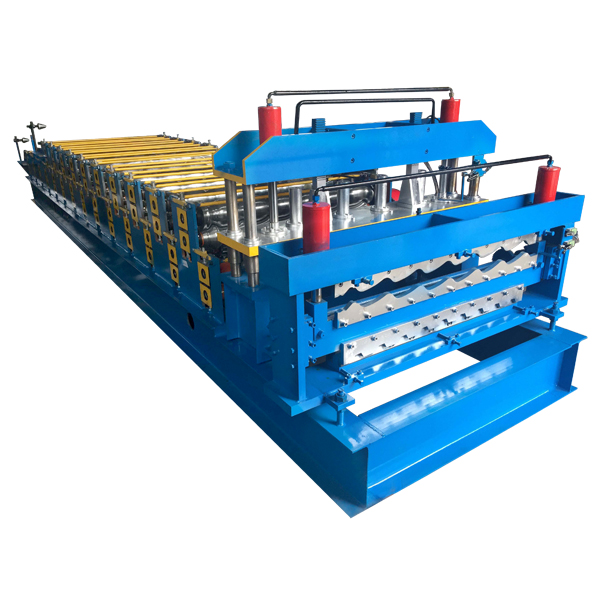

Low MOQ for Automatic Ceiling Grid T Bar Sheet Metal Roll Forming Machines - Factory Directly supply Xh 840/850 Double Layer Tile Forming Machine Roof Tile Roll Forming Machine – Haixing Industrial Detail:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Factory Directly supply Xh 840/850 Double Layer Tile Forming Machine Roof Tile Roll Forming Machine, Let’s cooperate hand in hand to jointly come up with a beautiful long term. We sincerely welcome you to definitely check out our enterprise or make contact with us for cooperation!

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Double Layer Tile Forming Machine, Double Layer Tile Forming Machine Roof Tile Roll Forming Machine, Manual Roof Tile Making Machine, Please feel cost-free to send us your specifications and we’ll respond to you asap. We’ve got a professional engineering team to serve for the every single detailed needs. Free samples may be sent for you personally to know far more facts. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Sales Service

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad, we will arrange the technician, but the buyers should take all the cost, including visa, round trip ticket etc.

Roof roll forming machine parameters

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 2 set

Electric-motor: 1 set

Cutting device: 2 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Call of Duty: Black Ops 4 Zombies Voyage of Despair easter eggs | Steel Downpipe Roll Forming Machine

Fallout 76 Bobbleheads Locations Guide | Roof Sheet Curving Machine

Low MOQ for Automatic Ceiling Grid T Bar Sheet Metal Roll Forming Machines - Factory Directly supply Xh 840/850 Double Layer Tile Forming Machine Roof Tile Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Special Design for Rain Water Forming Machine -...

-

Cheap PriceList for Used Decoilers - C channel...

-

Hot sale Cold Track Roll Forming Machine - Met...

-

factory customized Angle Purlin Roll Forming Ma...

-

Wholesale Dealers of Bending Metal Machine - A...

-

Original Factory Guardrail Forming Machine - C...