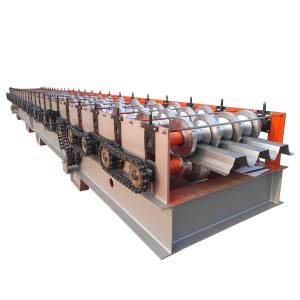

Our light steel keel machine manufacturers can be designed according to the buyer’s samples or drawings. The work Flow for the galvanized metal studs and tracks roll forming machine is as follows: Decoiler → Feeding Guide → Roll Forming → Cut-to-length → Run out table.

|

light steel keel machine manufacturers parameters |

||

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | As customer need |

| 3 | Thickness of the plate | 0.5-1.2mm |

| 4 | De-coiler | Manual one, can load 3 tons raw material |

| 5 | Rollers for forming | 18 rows |

| 6 | Diameter of the roller | Φ52mm |

| 7 | Rolling material | Carbon steel 45# |

| 8 | Main motor power | 4kW |

| 9 | Productivity | 8-12m/minute |

| 10 | Cutting method | Hydraulic mold cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kW |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 25mm |

| 16 | Main structure of the machine | 300H steel |

| 17 | Weight | About 6.5T |

| 18 | Dimensions | 5.5*1.0*1.5m |

| 19 | Voltage | 380V/50Hz/3 phases (changeable as needs) |

Components:

Manual decoiler ——————————————1 set

Guiding platform —————————————–1 set

Main machine of roll forming ————————–1 set

Electric motor ———————————————1 set

Cutting device ———————————————1 set

Hydraulic station ——————————————1 set

PLC control ————————————————1 set

Supporter table ———————————————1 set

light steel keel machine manufacturers details

light steel keel machine manufacturers Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).