Light keel forming machine parameters

| 1 | Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

| 2 | Thickness of coil sheet | 0.2-0.6mm |

| 3 | Coil width | as customer’s profile drawing requirement |

| 4 | Effective width | as customer’s profile drawing requirement |

| 5 | Material of mainframe | welded by 600mm steel plate |

| 6 | Diameter of Solid shaft | 40mm, high-grade 45# steel |

| 7 | Roller | Cr12, quenched and tempered treatment,

hard chrome plated 0.05-0.07mm |

| 8 | Thickness of middle plate | Memorial archway |

| 9 | Forming station | 10 rows |

| 10 | Drive type | Gear |

| 11 | Power of main motor | 5.5 kw, Lichao, Shanghai, with reducer |

| 12 | Servo motor | 1.5KW |

| 13 | Forming speed | About 20-30m/min |

| 14 | Hydraulic pump station | 5.5 kw, 40# hydraulic oil |

| 15 | PLC | DELTA(TAIWAN)/Mitsubishi |

| 16 | Material of razor blades | Cr 12, quenching 58-62℃ |

| 17 | Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy ±1mm, far better than industrial standard ±3mm. |

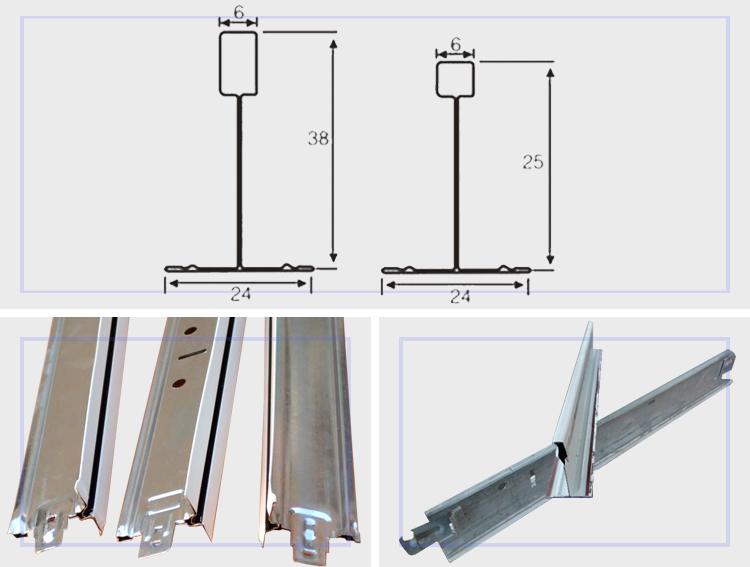

Light keel forming machine Details

FAQ

Q: How is this machine’s service life?

A: In the normal maintenance, the service life at least 8 years.

Q: Can you be responsible for transport?

A: Yes, please tell me the destination port or address. We have rich experience in transport.

Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q: How many workers operate this machine to manufacture?

A: Only 1-2 worker.