Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Leading Manufacturer for Hot Sale Philippines Corrugated Steel Sheet Roll Metal Roof Wall Tile Trapezoid Making Forming Machine, In case you have the requirement for almost any of our products and solutions, you should contact us now. We have been looking forward to hearing from you soon.

Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Corrugated Sheet Roll Forming Machine, Corrugated Steel Sheet Metal Roof Wall Tile Making Machine, Philippines Corrugated Sheet Machine, When It produced, it making use of the world’s major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a “people-oriented, meticulous manufacturing, brainstorm, make brilliant” company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we’ll be delighted to serve you.

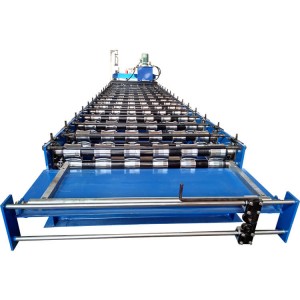

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

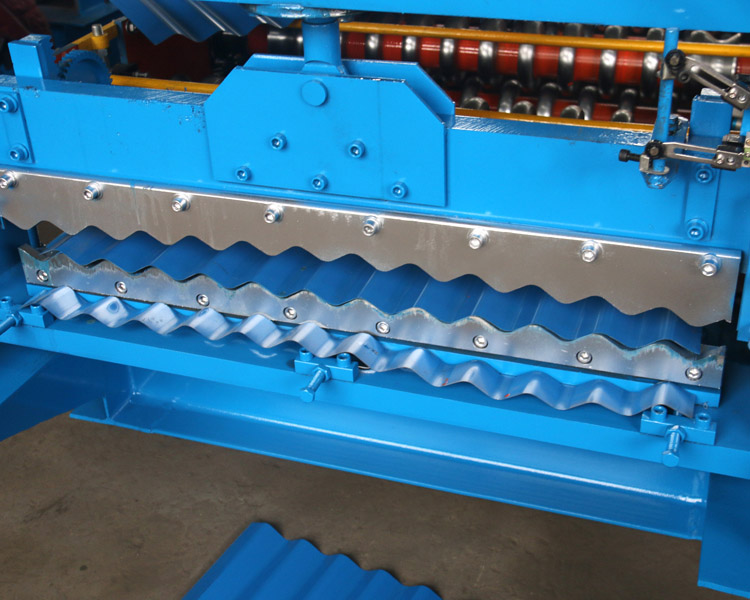

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Top Suppliers Speed Reliable Process Automatic ...

-

Factory Cheap Pro Screw-joint Curve Steel Roof ...

-

Reasonable price for Full Automatic Door Frame ...

-

Super Purchasing for Speed Steel Color Sheet Me...

-

Reliable Supplier Angle Programming CNC Metal P...

-

China New Product Steel Tech Roofing Double Lay...