With advanced technologies and facilities, strict good quality manage, reasonable rate, superior assistance and close co-operation with shoppers, we have been devoted to supplying the very best price for our consumers for Leading Manufacturer for Hot Sale Galvanized Ridge Roofing Cap Gutter Cold Roll Forming Machine, Let’s cooperate hand in hand to jointly make a beautiful upcoming. We sincerely welcome you to pay a visit to our company or speak to us for cooperation!

With advanced technologies and facilities, strict good quality manage, reasonable rate, superior assistance and close co-operation with shoppers, we have been devoted to supplying the very best price for our consumers for Aluminum Mobile Seamless Gutter Machine For Rainwater, Half Round Gutter Roll Forming Machinery, Metal Gutter Roll Forming Machine, We’ve more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the “client first” principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information remember to do no hesitate to contact us..

|

roof ridge making machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

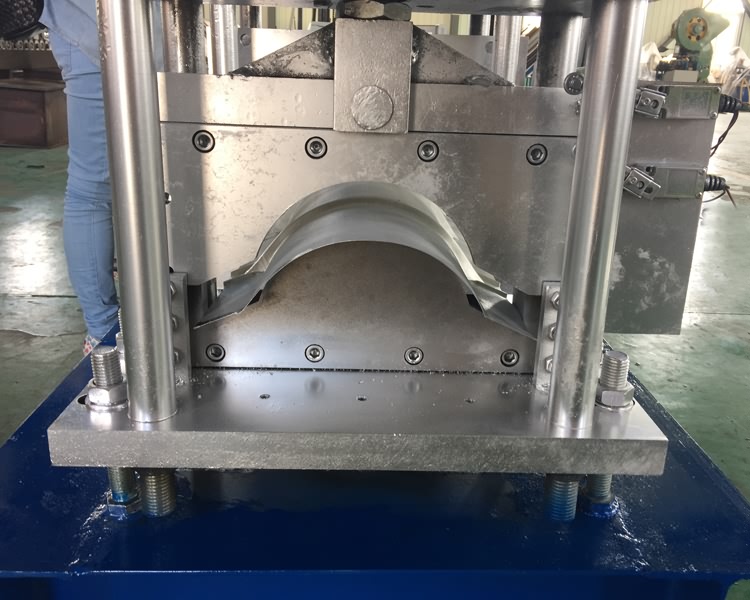

Machine details:

Roof ridge making machine package and shipment details:

Standard export packing: 1 x 40GP container, main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.