paramèter machine

|

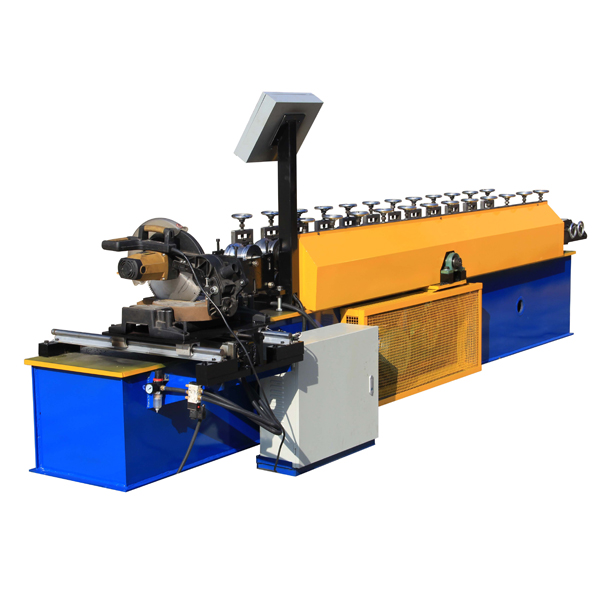

Roller rana lawang muter mbentuk mesin |

||

| 1 | bahan specification | Aluminium, galvalume, galvanis lan wis dicet galvanized baja. |

| 2 | kekandelan | 0.5mm kanggo 1.0mm. |

| 3 | daya motor utama | 4.5kw. |

| 4 | daya stasiun Hydraulic | 3kw. |

| 5 | jembaré dipakani | Gumantung ing model saka profil. |

| 6 | kaku ngasilaken | 235Mpa (33KSI) ~ 350Mpa |

| 7 | kacepetan mbentuk Roll | 12-15 m / menit. |

| 8 | nglereni toleransi | +/- 2.5mm (length≤5000mm); +/- 3.0mm (5000mm) |

| 9 | manual uncoiled | Max. Capacity: 3000kgs

decoiler manual |

| 10 | diameteripun utama Coil | 508mm / 610mm |

| 11 | Tegangan | 380v / 50hz / 3 phase |

| 12 | Nomer saka stands | 12 stands / stasiun / pasangan kanggo saben sistem mbentuk muter |

| 13 | materi roller | bahan dhuwur No.45 palsu baja, ditutupi karo chrome hard. |

| 14 | materi batang aktif | bahan dhuwur No.45 karbon manut kekarepané baja, kang bisa nambah fitur mekanik terpadu batang. |

| 15 | unsur Electric | PLC control panel, transducer imported from Mitsubishi of Japan.

liyane unsur wholesale misuwur saka China. |

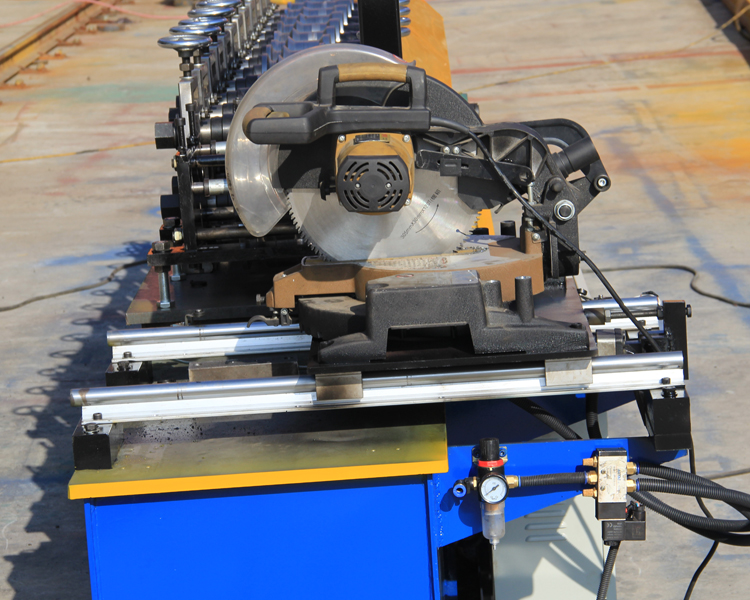

| 16 | glathi cutter | Cr12 jamur baja karo perawatan sirep. |

tampilan Gambar Machine

Details Packaging :

1. Machine wis dijamin dening film plastik.

2. kothak kontrol PLC, spare parts lan bagean cilik liyane sing dikempalken dening kothak karton kayu.

Sarat:

1. Delivery: ing 60 dina sawise nampa simpenan.

2. Paket: kaca paket standar kanggo wadhah.

3. Pembayaran: TT (30% dening TT ing advance, 70% dening TT sawise mrekso mesin sadurunge layang).

layanan Sales:

1. We nyedhiyani technical support kanggo kabèh urip mesin kita.

2. Yen panuku kudu Teknisi kanggo pindhah ing luar negeri, kita bakal ngatur Teknisi, nanging panuku kudu njupuk kabeh biaya, kalebu visa, babak tiket trip etc.