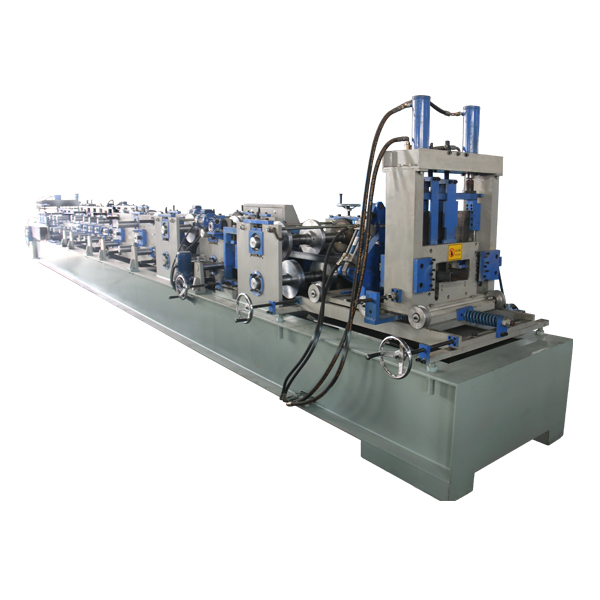

Otomatis CZ aliran interchange purlin proses mesin:

Manual decoiler- punching muter hole- mbentuk ngecor mesin- press- kontrol PLC box- hydraulic system- kirim cut- Tabel output.

|

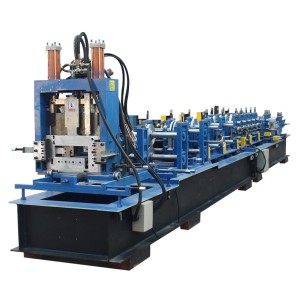

Purlin muter mbentuk mesin |

||

| 1 | Cocog kanggo proses | piring steel |

| 2 | rollers | 18 larik (Sadurunge lan sawise gawe tingkat lan ora ngandhut timbal kanggo ngirim liwat) |

| 3 | Ukuran | 11 * 1.3 * 1.5m |

| 4 | Power | 11.5kw + 7.5kw |

| 5 | Kekandelan saka piring | 1-3mm |

| 6 | produktivitas | 8-10m / min |

| 7 | kekandelan plate Tengah | 20mm |

| 8 | cara Driving | 2.6-inch China gembong lan link chain |

| 9 | Diameter lan materi saka sumbu mbentuk | 80mm |

| 10 | bobot | About 8.5T |

| 11 | Tegangan | phase 380V 50HZ3 |

| 12 | materi Roll | GCr15 (prewangan baja) Chrome hard dilapisi sawise perawatan panas |

| 13 | materi batang | 40Cr modulasi saka perawatan panas sawise polishing hard krom plating |

| 14 | Loro-lorone ing materi wall | A3 baja |

| 15 | frame | International H-Beam |

| 16 | materi Blade | Cr12Mov |

| 17 | mbentuk wheel | Prewangan quenching baja |

mesin iki jembaré bagéan ngisor iki:

mesin Single-mburi dipakani (max kapasitas 5T), dipakani gawe tingkat, sistem mbentuk, mekanisme (siji tembung asli), straightening Ing bolongan siji + pindho, Sawise mbentuk sistem nyukur, Supporting platform materi (6m)

tampilan Gambar Machine

Sarat:

1. Delivery: ing 60 dina sawise nampa simpenan

2. Paket: kaca paket standar kanggo wadhah

3. Pembayaran: TT (30% dening TT ing advance, 70% dening TT sawise mrekso mesin sadurunge layang)