In the past few years, our organization absorbed and digested state-of-the-art technologies equally at home and abroad. Meanwhile, our enterprise staffs a team of experts devoted towards the growth of Hot-selling Coil Slitting Production Line, We warmly welcome customers, business associations and friends from all over the world to contact us and seek cooperation for mutual benefits.

In the past few years, our organization absorbed and digested state-of-the-art technologies equally at home and abroad. Meanwhile, our enterprise staffs a team of experts devoted towards the growth of Coil Slitting Production Line, Metal Slitting Line, Slitting Machine, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions and ideas with us!!

The whole production line include the 15 Tons hydraulic decoiler with loading car one set, slitting machine one set,scrap winder two sets, tension stand one set, and automatic recoiler one set.

Before the installation,we will provide the foundation drawing, and the customer prepare the foundation as the drawing.

Our engineer will install the machine overseas and training the workers how to start the machine,change the slitting blade, and other adjustment.

To make the coil material feed into the slitting machine and tension machine smoothly, need make two storage pits on the ground.

|

Slitting line machine parameters |

||

|

Raw Material (if the material is stainless steel, please tell in advance) |

1 | Material: carbon steel and others |

| 2 | The thickness of the material: 0.4mm-6mm. | |

| 3 | Width: 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm | |

| 4 | Input width: 600-1600mm | |

|

Hydraulic decoiler with car |

1 | The inner size: 450–610mm |

| 2 | The Max width: 1250mm | |

| 3 | The capacity: 15T 20Ton or more | |

|

Flatting and Cutting System |

1 | 2 shafts for feeding coil, 9 shafts for flatting |

| 2 | material of flatting: 42CrMo heat treated 50-52. | |

| 3 | hydraulic system. | |

| 4 | 2 sets cutting blade | |

| 5 | width of cutting: 600mm–1220mm. | |

| 6 | the material of blade mould: Gr12MoV | |

| 7 | power: 22KW Motor with ZQ650 Reducer | |

|

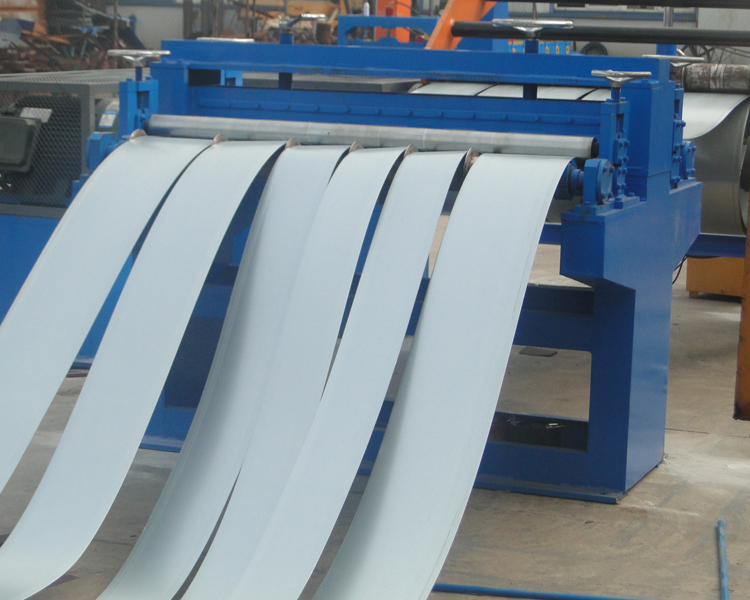

Slitting system |

1 | The width range: 200–1300mm |

| 2 | The precious of the width: ±1mm | |

| 3 | The speed of slitting: 25m/min | |

| 4 | The width can be change. | |

| 5 | Material of the slitting: Cr12MoV. | |

| 6 | Hardness of slitting blade: HRC5860. | |

| 7 | Slitting: 2~3mm 6 lines. | |

| 8 | Quantity of blades: 10 sets. | |

| 9 | Width of side scrap: 3-15mm | |

| 10 | The precious of side scrap: ±0.5mm | |

| 11 | Quantity of side scrap: 2 strips | |

| 12 | Power of the slitting: 37KW, 1000r/min, with ZQ750 Reducer. | |

|

Control System |

1 | Screen: 3.2inch button screen |

| 2 | PLC: Delta | |

|

Electrical collecting machine with car |

1 | Material inner: 550-650mm |

| 2 | Max Coil width: 1500mm | |

| 3 | Carrying capacity: 5T | |

| 4 | Automatic relax or collect | |

| 5 | Power: 22KW | |

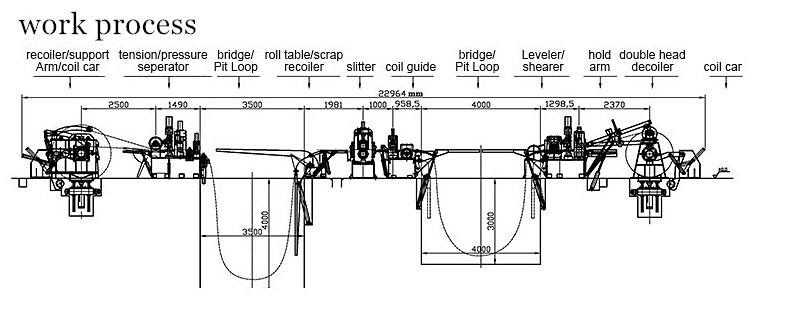

Working process

Decoiler —-flatting and cutting—slitting—–flatting and collecting

Machine picture display

We also supply large slitting line as below:

This is composed of frame, bearing-stand, recoiling shaft, expand recoiling device and plate, movable supporting stand, accompany of decelerator, direct-current speed adjustable motor: 85KW and direct-current electronic cabinet, etc.

Designed with the seamless expand and shrink structure and hydraulic clip-mouth so that when the heads feed into the clip-mouth, it will close automatically and start winding.

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Sales service:

1. We provide technical support for the entire life of the machine.

2. If the buyer needs a technician to go abroad, we will arrange the technicians, but the buyer should bear all the expenses, including visas, round-trip tickets, etc.

-

Manufactur standard Cnc Press Brake / 40ton/250...

-

OEM China Heat Treatment Cutter Roof Panel Tile...

-

Rapid Delivery for Color Coated Coil Difference...

-

ODM Manufacturer Aluminum Zinc Stone Coated Roo...

-

ODM Factory Galavinzed Steel Roofing Sheet Roll...

-

Hot-selling Light Steel Angle Bar Roll Forming ...