It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for Hot sale Hydraulic Crimp Curved Steel Roofing Roll Forming Machine, Living by good quality, enhancement by credit history is our eternal pursuit, We firmly feel that soon after your visit we will become long-term associates.

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for Corrugated Steel Crimping Machine, Crimp Curved Roll Forming Machine, Crimp Curved Roofing Sheet Machine, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions and ideas with us!!

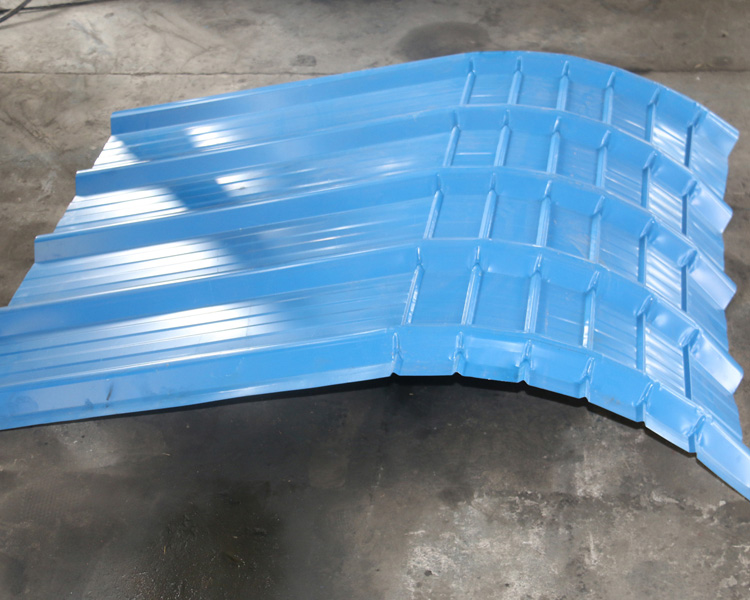

Application of Curved Roof Panel Roll Forming Machine

For architecture: making roof panel, wall panel, ceiling panel, etc.

For Industry: making refrigerating room panel, automobile panel, electric appliance housing, etc.

|

Curved Roof Panel Roll Forming Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

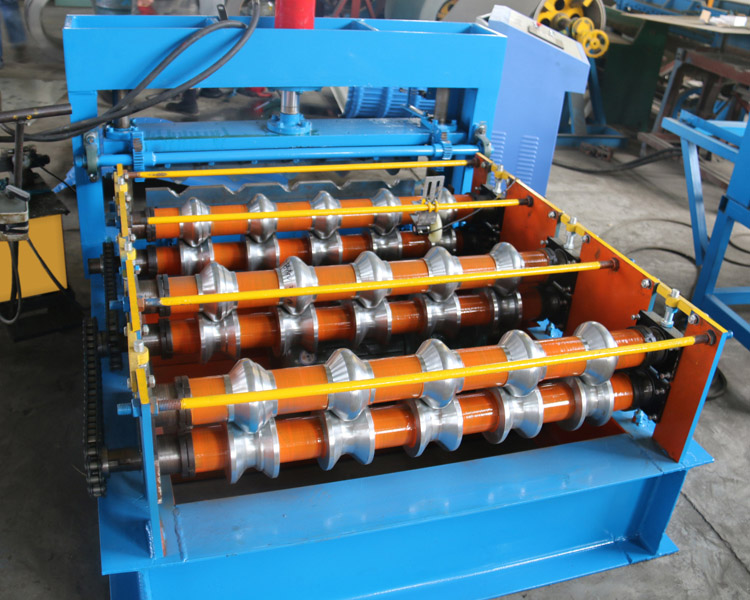

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

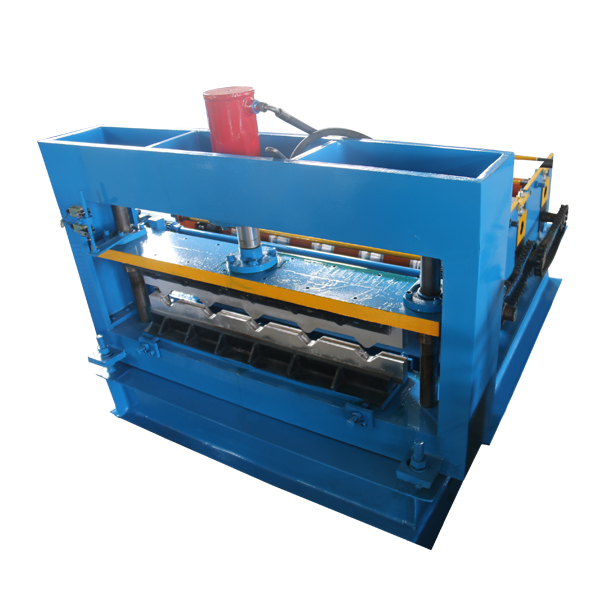

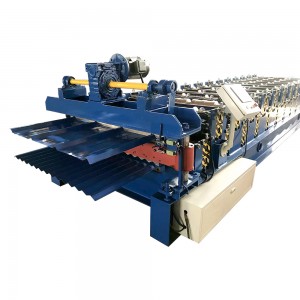

Machine Photos:

Package and shipment details:

1. Main roll forming machine package by plastic film

2. Main machine spare parts package by paper box

3. We have a professional technician load to ensure that the goods are loaded into the container without any damage.

4. Transportation: machines need one 20 feet container to hold.

5. Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

-

Bottom price China 4500 Ton Metal Frame Sheet S...

-

Bottom price Hot Sale Hebei Multifunctional Reb...

-

Good quality Double Layer Roof Panel Metal Roof...

-

Newly Arrival China Double Layer Roof Sheet Rol...

-

High Quality Galvanized Steel Roofing Panel She...

-

OEM/ODM China Hydraulic Steel Coil Decoiler For...