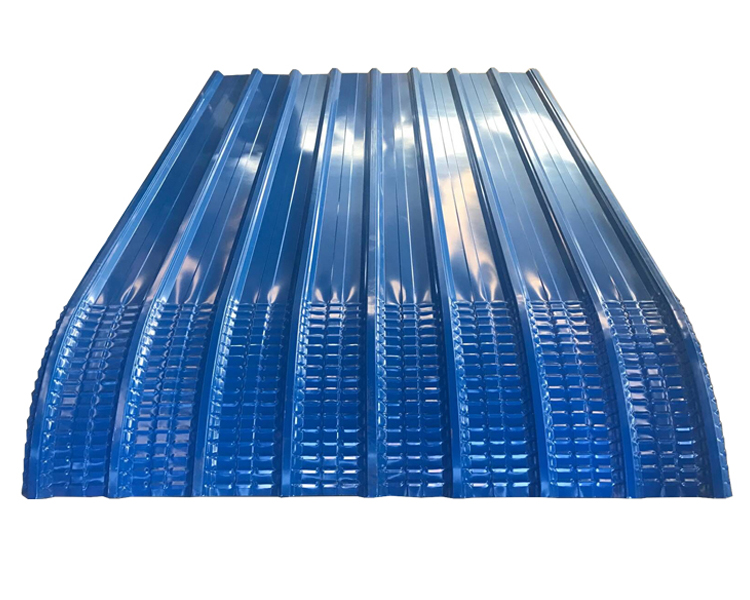

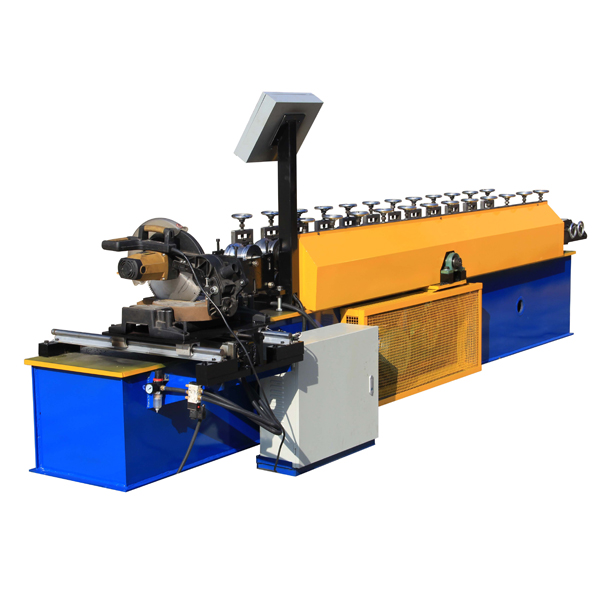

High Quality for Steel Deck Roll Former - Roof Panel Curving Machine – Haixing Industrial Detail:

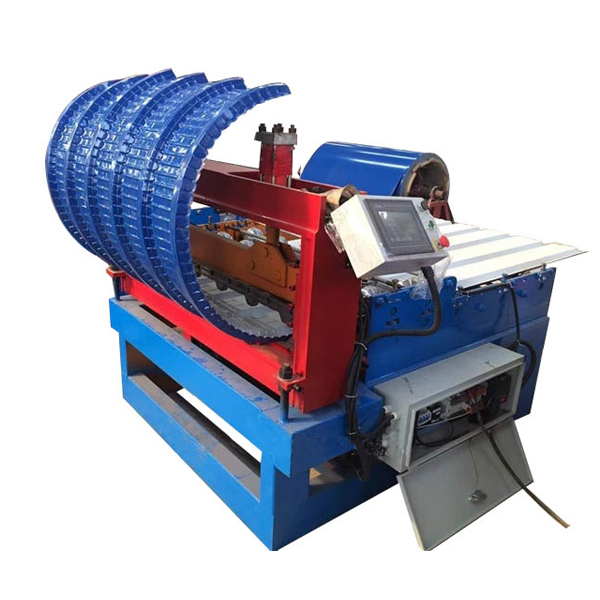

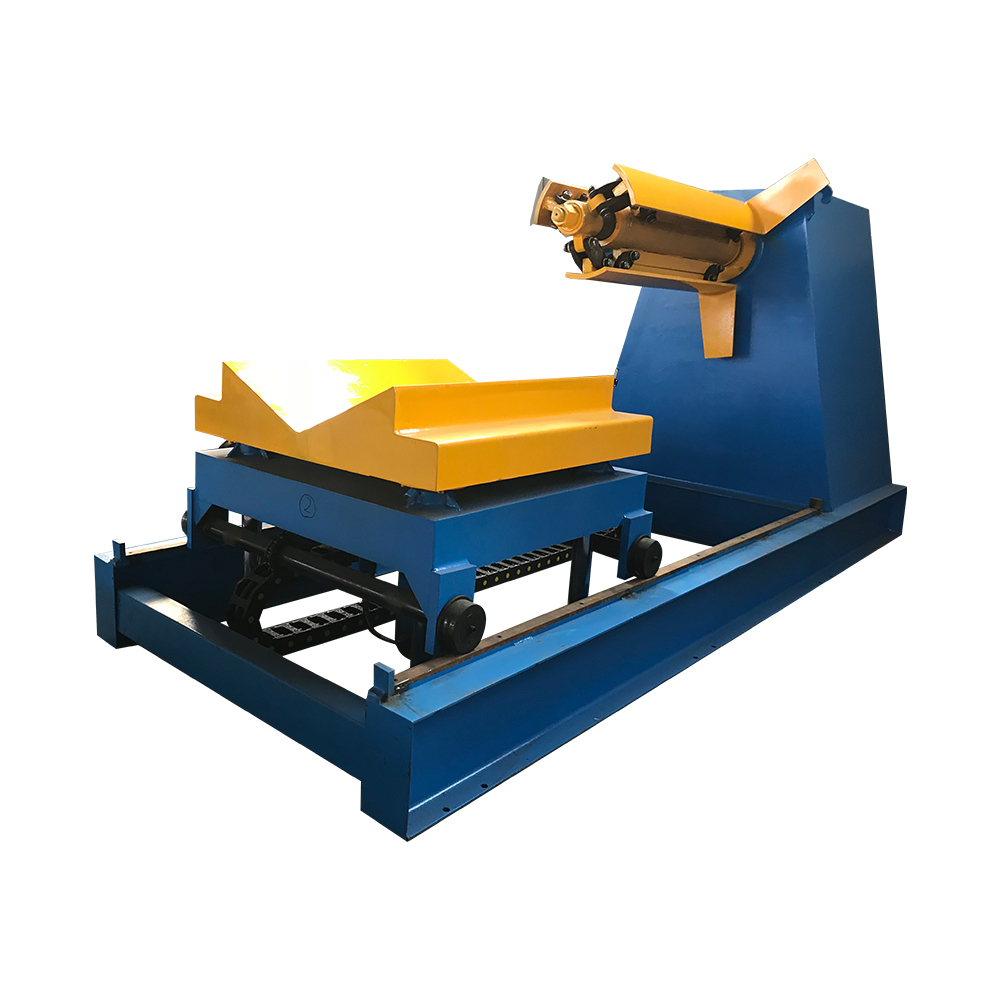

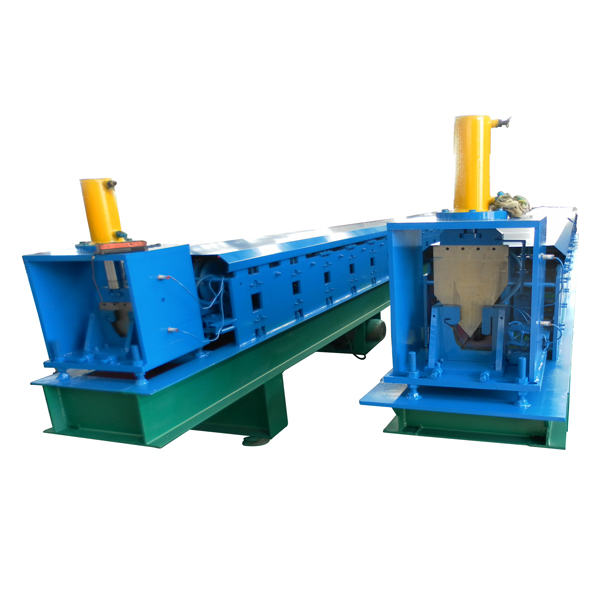

Roof panel curving machine consist of decoiler and its base, coil sheet guiding equipment, roll forming system, post cutting equipment, pressing equipment, post-cutting system, hydraulic station, controlling system, supporter table.

|

Roof curving roll forming machine parameters |

||

| 1 | Suitable material | Color galvanized steel coil |

| 2 | Thickness of raw material | 0.3-0.7mm |

| 3 | Yield strength of material | 235Mpa |

| 4 | Working Speed | 8-10m/min |

| 5 | Step distance | Adjustable according to requirement (>=250mm) |

| 5 | Decoiler’s loading capacity | Max. Capacity: 5000kgs |

| 6 | Controlling system | PLC with best brand |

| 7 | Power | 3+3kw |

| 8 | Voltage | 380V 50Hz 3phases |

| 9 | Cutting way | Motor drive or Hydraulic drive |

| 10 | Machine’s size | about 2m*1.5m*1.4m (Depend on final design) |

| 11 | Total Weight | 2.2Tons |

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

The Top Yachts at the Fort Lauderdale International Boat Show | Roof Sheet Curving Machine

Vellum Venom: 1992 Cadillac Brougham | Roof Sheet Curving Machine

High Quality for Steel Deck Roll Former - Roof Panel Curving Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Factory For Glazed Tile Roof Panel Roll Forming...

-

New Arrival China Ceiling T-Grid Roll Forming M...

-

2017 China New Design Hydraulic Pipe Punching M...

-

Factory Cheap Roofing Ridge Cap Cold Roll Formi...

-

Wholesale Price Sheet Bending Machine - Roller...

-

Wholesale Arch Building Sheet Roofing Making Ma...