We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for High definition Kxd Metal Roofing Sheet Crimping Machine Curving Machine, Every one of the views and strategies are going to be tremendously appreciated! The good cooperation could enhance each of us into much better development!

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for Curving Machine, Roof Crimping Machine, Roof Curving Machine, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our goods or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

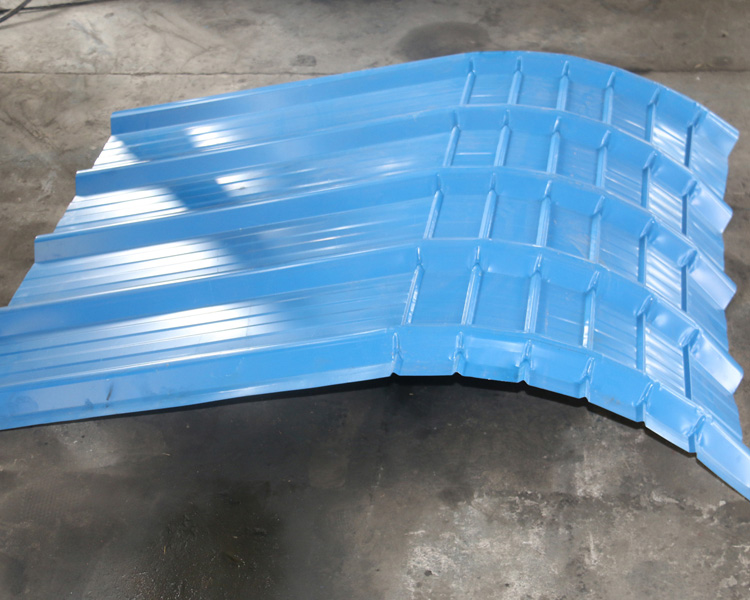

Application of Curved Roof Panel Roll Forming Machine

For architecture: making roof panel, wall panel, ceiling panel, etc.

For Industry: making refrigerating room panel, automobile panel, electric appliance housing, etc.

|

Curved Roof Panel Roll Forming Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

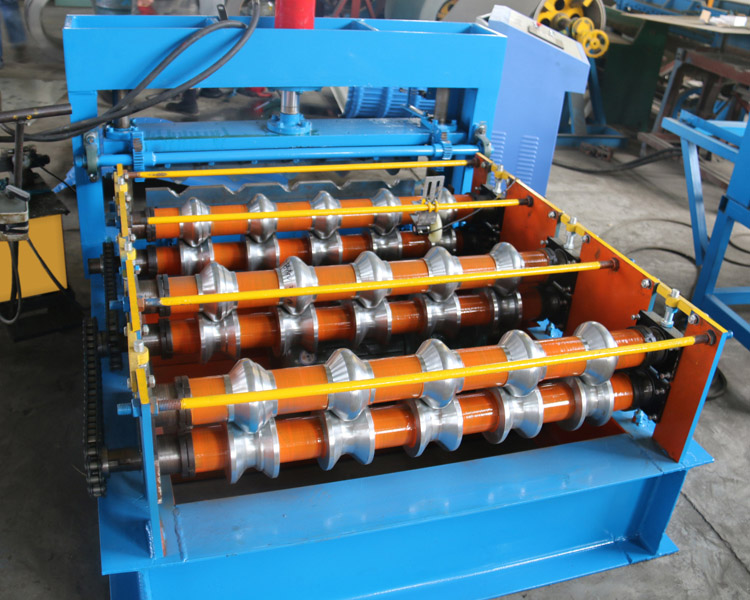

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

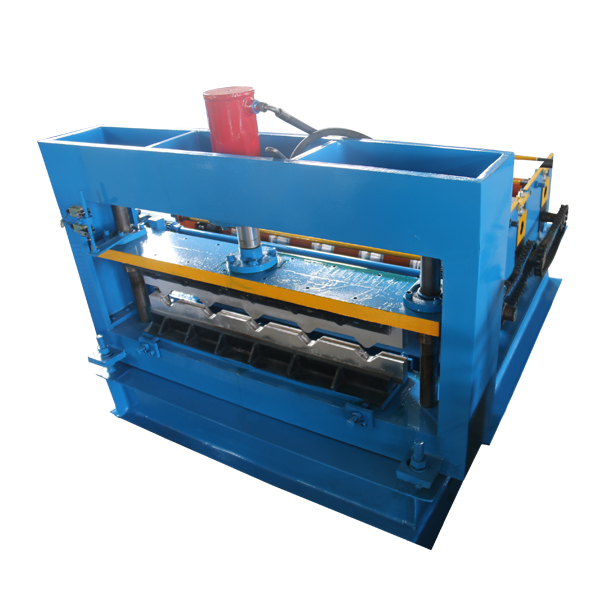

Machine Photos:

Package and shipment details:

1. Main roll forming machine package by plastic film

2. Main machine spare parts package by paper box

3. We have a professional technician load to ensure that the goods are loaded into the container without any damage.

4. Transportation: machines need one 20 feet container to hold.

5. Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

-

China Manufacturer for Low Plc Controlled Multi...

-

Cheap price Metal Roofing Galvanized Aluminum C...

-

Low MOQ for Dx51d Z100 Galvanized Steel Coil Fo...

-

Factory best selling Multifunctional Wf67k-100t...

-

High Quality Yx18-77-760/1040 Corrugated Roof P...

-

Supply OEM/ODM Hydraulic Steel Plate Folding Ma...