While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Good User Reputation for Made In Used Metal Roof Tile Roll Forming Machine, Let’s cooperate hand in hand to jointly come up with a beautiful long term. We sincerely welcome you to definitely check out our enterprise or make contact with us for cooperation!

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Metal Roof Tile Roll Forming Machine, Roof Tile Roll Forming Machine, Used Roof Tile Roll Forming Machine, Looking forward, we’ll keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we’ll supply high quality solutions to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

The finished product of C25 Roof roll forming machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

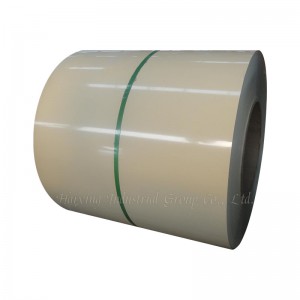

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1140mm |

| 12 | Effective width | 1050mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine details

Package and shipment details

Standard export packing: 1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

The advantages of automatic roofing sheet roll forming machine:

1.Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2.Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable,maintenance-free.

3.We can make and design will kinds of roll forming machine according to customer’s request.