Our staff are usually in the spirit of “continuous improvement and excellence”, and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer’s belief for Good quality Eb1250 Magnetic Electric Metal Sheet Bending Machine, We’ve been now searching ahead to even increased cooperation with abroad consumers determined by mutual positive aspects. In case you are intrigued in almost any of our solutions, remember to experience totally free to speak to us for additional facts.

Our staff are usually in the spirit of “continuous improvement and excellence”, and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer’s belief for Magnetic Bending Machine, Magnetic Electric Bending Machine, Metal Sheet Magnetic Bending Machine, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they’re created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Functions and Characteristics

1. Steel- welded construction, standard upper and lower dies,vibration to eliminate inner stress,hydraulic transmission system,foot pedal with emergency stop.with high strength and good rigidity.

2. Hydraulic top-drive, steadiness and reliability. Mechanical stop, steel torsion bar to maintain synchronization, with high precision.

3. Motorized-adjusting device for back gauge and ram’s stroke, DRO for back gauge and ram stroke.

4. Deflection compensation unit installed under the worktable.

5. Manual crowned lower die holder is adopted for the machine above 250 tons.

6. DRO to display the values of back gauge and ram stroke.

|

Sheet metal bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

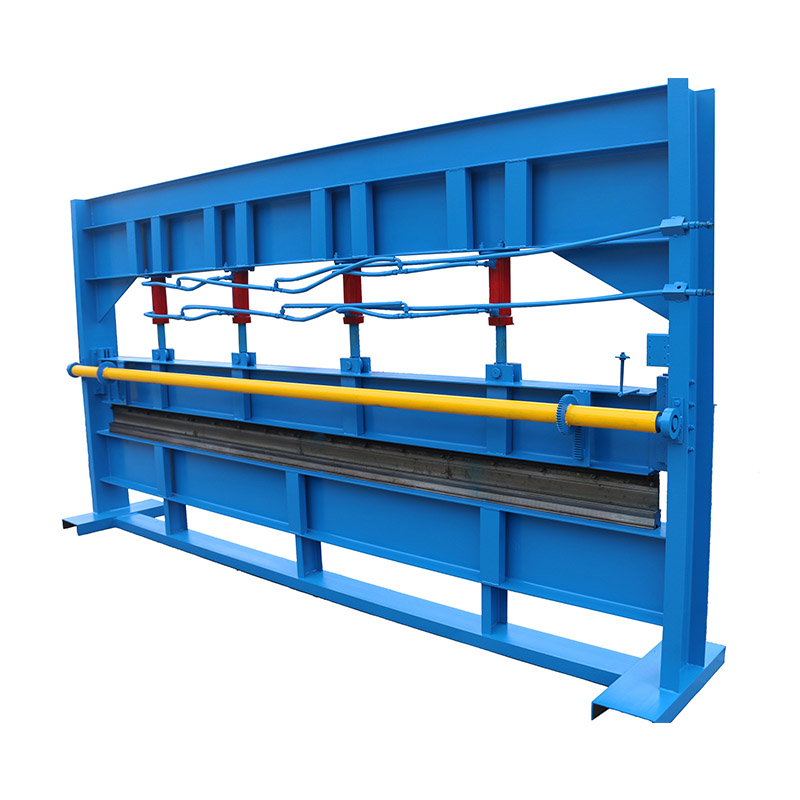

Machine photos

Sales service:

1. We provide technical support for the entire life of the machine.

2. If the buyer needs a technician to go abroad, we will arrange the technicians, but the buyer should bear all the expenses, including visas, round-trip tickets, etc.

-

Manufacturer for Direct Manufacture Precision E...

-

Factory directly 2018 Metal Roofing Glazed Tile...

-

factory Outlets for New Technology Machine Shee...

-

Factory supplied Electromagnetic Manual Sheet M...

-

China Wholesale Most Popular Metal Roofing Doub...

-

Best quality Manufacture Sells Dw89nc Hydraulic...