We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for Good Quality China Hydraulic Electric Roof Panel Curving Machine, Crimping Machine. Arching Machine, Welcoming interested businesses to cooperate with us, we look forward to owning the opportunity of working with companies around the planet for joint expansion and mutual results.

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for China Roof Panel Curving Machine, Crimping Machine, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

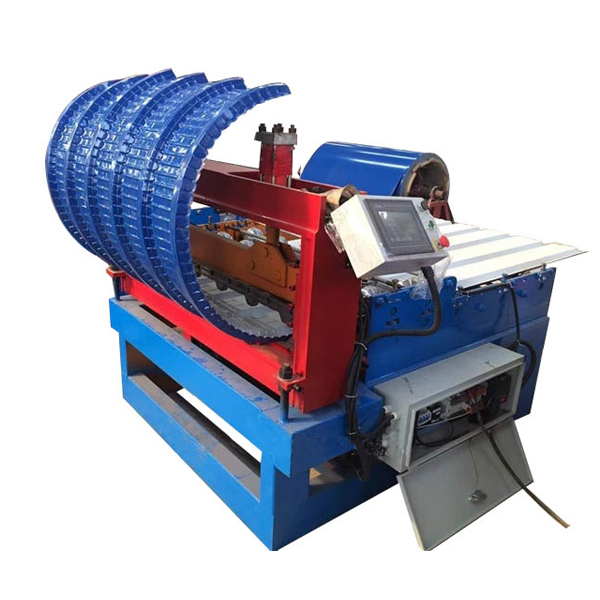

Roof panel curving machine consist of decoiler and its base, coil sheet guiding equipment, roll forming system, post cutting equipment, pressing equipment, post-cutting system, hydraulic station, controlling system, supporter table.

|

Roof curving roll forming machine parameters |

||

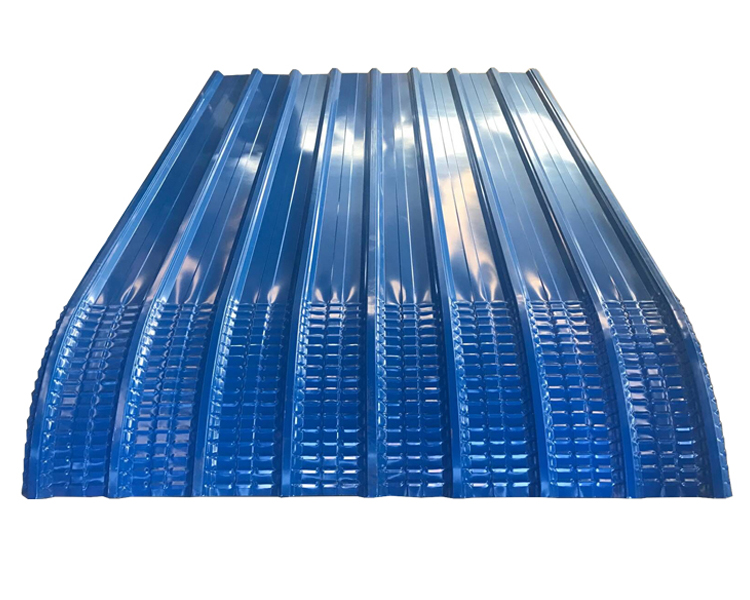

| 1 | Suitable material | Color galvanized steel coil |

| 2 | Thickness of raw material | 0.3-0.7mm |

| 3 | Yield strength of material | 235Mpa |

| 4 | Working Speed | 8-10m/min |

| 5 | Step distance | Adjustable according to requirement (>=250mm) |

| 5 | Decoiler’s loading capacity | Max. Capacity: 5000kgs |

| 6 | Controlling system | PLC with best brand |

| 7 | Power | 3+3kw |

| 8 | Voltage | 380V 50Hz 3phases |

| 9 | Cutting way | Motor drive or Hydraulic drive |

| 10 | Machine’s size | about 2m*1.5m*1.4m (Depend on final design) |

| 11 | Total Weight | 2.2Tons |

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

factory low price Roof System-t Shape Corrugate...

-

100% Original Roll Forming Manufacturing Metal ...

-

Special Price for Fx 1.5t 5t 10t Manual Hydraul...

-

OEM/ODM China Steel Roof Truss Making Machinery...

-

Supply OEM/ODM Double Layers Metal Sheets Roofi...

-

Cheap price New Condition Fast Speed Cutting Do...