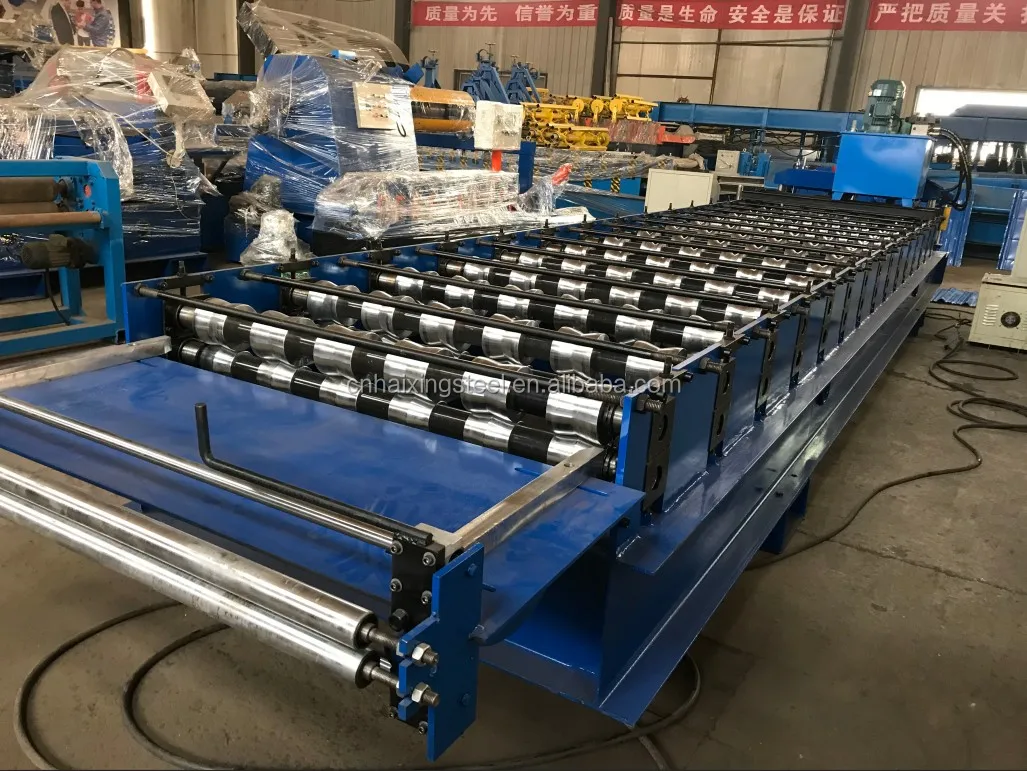

1. glazed roof panel step tile cold roll forming machine photos showing

2.Technical process of glazed roof panel step tile cold roll forming machine

Decoiler—–feeding—– leveling —– cutting —–roll forming —– punching —– output table

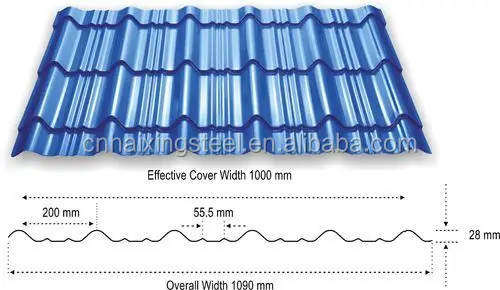

1.Technical data of glazed roof panel step tile cold roll forming machine

| Technical Parameters (some depend on the final design) | ||

| 1 | Style | glazed roof panel step tile cold roll forming machine |

| 2 | Machine dimension | 7500*1450*1600mm |

| 3 | Total wight | 5200kgs |

| 4 | Forming steps | 15rows |

| 5 | Forming speed | 1.5-3.0m/min |

| 6 | Hydraulic station power(Kw) | 4kw |

| 7 | Diameter of shaft | 70mm |

| 8 | Hydraulic pressure | 18-20 MPa |

| 9 | Electric condition | 380V/3Phase/ 50HZ |

| 10 | Suitable to process | Color steel plate(G330 or G350 or G550 ) |

| 11 | Manual uncoiler max capacity | 5000kgs |

| 12 | Control system | PLC |

| 13 | Raw material thickness | 0.3-0.8mm |

| 14 | Effective width | 1000mm |

| 15 | Material width | 1200mm |

| 16 | Main motor | 5.5Kw |

| 17 | Material of the cutting blade | Cr 12 quenched treatment 58℃-62℃ |

| 18 | Main Shaft Material

|

45# steel with finish turning |

| 19 | Roller materials | 45# Forging Steel with Chromium Plate |

| 20 | Machine Under Frame | 350 H beams |

2.Components of glazed roof panel step tile cold roll forming machine

| 1 | Manual uncoiler | 1 set |

| 2 | Sheet guiding equipment | 1 set |

| 3 | Roll forming system | 1 set |

| 4 | Pressing device | 1 set |

| 5 | Post-cutting equipment | 1 set |

| 6 | Hydraulic station | 1 set |

| 7 | Electric controlling system | 1 set |

| 8 | Support table | 2 pieces |

1.glazed roof panel step tile cold roll forming machine and uncoiler are nude packing (If you need, we can also packed it with water-proof plastic)

2. PLC control system and motor pump are packed with water proof paper,spare parts in carton box.

3.One set of machine needs a 40′ container to shipping.

1. Warranty :One year,and we will provide technical support for whole life of the equipment.

2. Delivery time: Within 35 days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.

WHY CHOOSE HAIXING INDUSTRIAL GROUP CO.,LIMITED

1) Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

2)Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3)Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit

We are Gold supplier with BV assessment and CE certificate.

4)Q: What can you do if the machine broken?

A: Our machine’s warranty period is 18 months,if the broken parts can’t repair

we can send the new parts replace the broken parts free,but you need pay the express cost yourself if after warranty period ,we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the equipment.

5) Q: Can you be responsible for transport?

A: Yes,please tell me the destination port or address we have rich experience in transport.

Company Profile Details

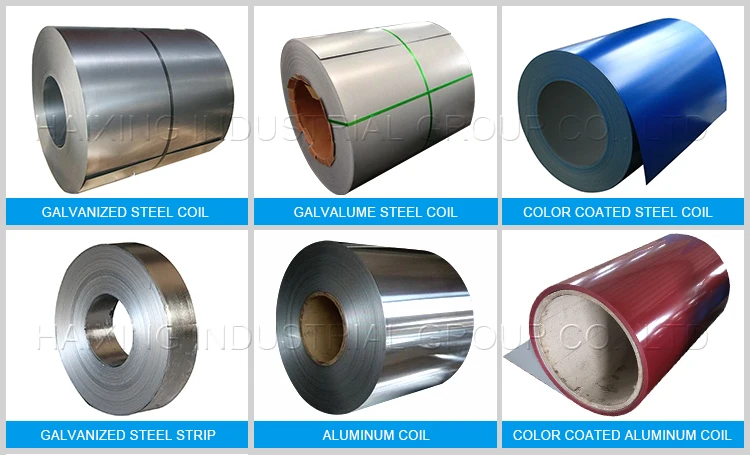

Tianjin Haixing Imp&Exp company are specializing in the production of all kinds of glazed roof panel step tile cold roll forming machine,glazed roof making machine, double roof making machine,floor deck machine,curve roof machine,ridge cap roof forming machine, different sizes roofing sheet, PPGI/ GI,Alu-Zinc steel coils ,Galvanized steel coils, Galvanized steel sheet,Galvalume steel coils/sheet, cold/ hot rolled sheet/coils,professional service and favorable price, satisfied with the quality,welcome to every customers come to visit and buy !

Roll forming machine and coils