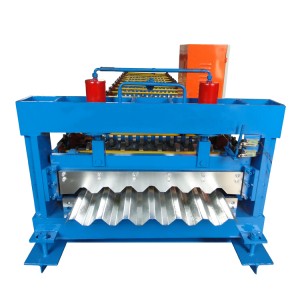

Galvanized Metal Roof Sheets Cold Forming Machinery parameters

|

1 |

Main motor power |

5.5KW |

|

2 |

Hydraulic motor power |

5.5KW |

|

3 |

Hydraulic pressure |

10-12MPa according to the oil pump and pump motor |

|

4 |

Voltage |

380V/ 3 phase/ 50 Hz (or as your requirements) |

|

5 |

Control system |

Automatic PLC control system |

|

6 |

Mainframe |

350/400H beams according to machine demands |

|

7 |

Wall sheet thickness |

16-22mm according to machine demands |

|

8 |

Chain size |

1 /1.2inch according to machine demands |

|

9 |

Feeding material |

Galvanized steel coil, color steel coil, aluminum steel coil |

|

10 |

Feeding thickness |

0.3-0.8 mm |

|

11 |

Productivity |

0 – 25m/min |

|

12 |

Roll station |

Common 11rolls or 25rolls |

|

13 |

Roller diameter |

70mm, 75mm, 80mm (depends on different design) |

|

14 |

Roller material |

45# steel |

|

15 |

Cutter material |

Cr12MOV |

|

16 |

Cr-plating size |

0.05 mm |

Galvanized Metal Roof Sheets Cold Forming Machinery production process

- Drawing confirmation——After confirming the final drawing with the customer, the team of 12 engineers worked out the diagram;

——After 5 verifications, the production manager arranges the procurement of raw materials according to the drawings;

- Start production——The company has 12 roughing machines, 20 finishing machines, and 30 cutting machines, starting to produce machine parts.

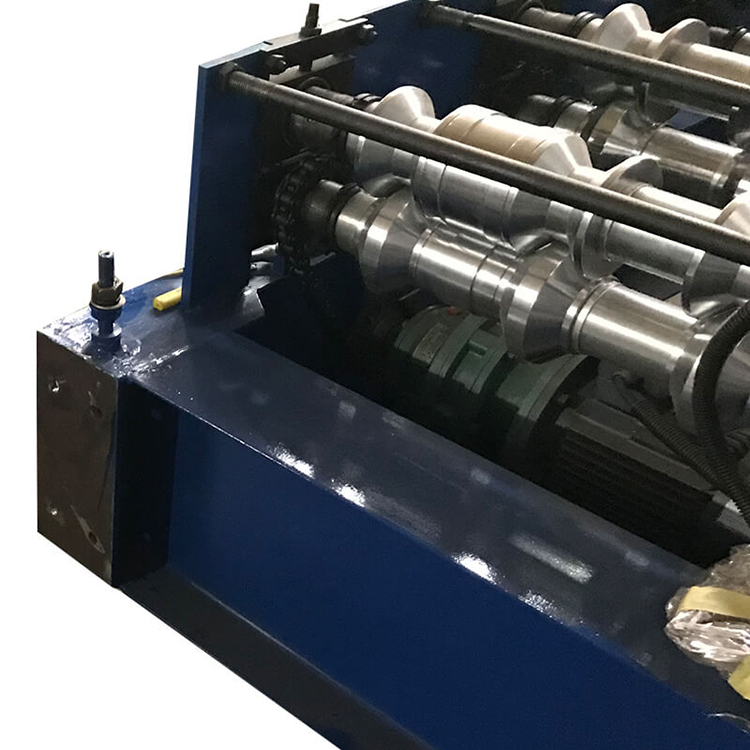

- Product Inspection——Wheels and axis: Test 90% of the wheels and shafts, test their accuracy and performance after processing. All the wheels and shafts are hot-chromed. ensuring that two quality inspectors use a film tester to measure the thickness of the hot-dip chrome plating to ensure that each place reaches 5 microns or more.

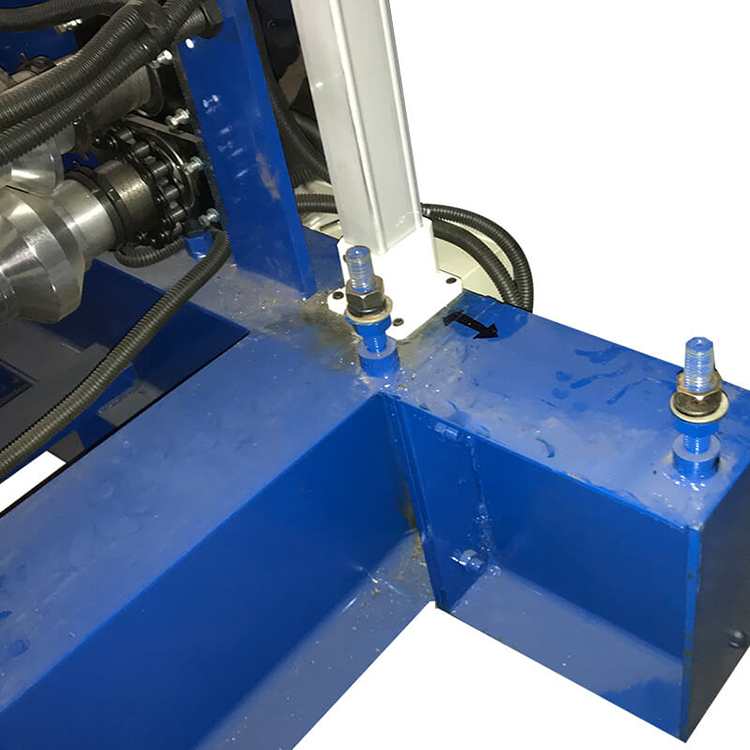

——Mainframe and medium plate: Verify the accuracy of the mainframe and the middle plate after cutting.

- Assembling machine parts——The assembly team consisted of 5 people and was assembled in one day.

Galvanized Metal Roof Sheets Cold Forming Machinery picture details

Why choose us?

Our company has a professional team of engineers and export team.

-

Engineer: 25 (2 engineers with more than 30 years of work experience, 5 engineers with more than 20 years of work experience, 8 engineers with more than 10 years of work experience, 10 engineers with more than 5 years of work experience);

-

Factory workers: 88;

-

Finance staff: 2;

-

Purchasing staff: 12;

-

Operator: 3;

-

Sales staff: 8;

-

After-sales staff: 5.

1. The main machine is covered with plastic film.

2. PLC control box, spare parts, and other small parts are packed by wooden cartons.

1)Q: Do you have after-sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3)Q: How does your factory do regarding quality control?

A: Quality is the priority. we always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers’ specifications, using top brand name components.

5) Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.