Fast delivery Automatic Decoiler For Roll Forming Machine - OEM Customized Metal Stud Roll Forming Machine Light Keel Roll Forming Machine – Haixing Industrial Detail:

Our purpose will be to fulfill our shoppers by offering golden assistance, fantastic price and high quality for OEM Customized Metal Stud Roll Forming Machine Light Keel Roll Forming Machine, Looking to the long run, a lengthy way to go, regularly striving to become the all employees with full enthusiasm, one hundred times the confidence and put our company built a beautiful environment, advanced merchandise, good quality first-class modern company and work hard!

Our purpose will be to fulfill our shoppers by offering golden assistance, fantastic price and high quality for Light Keel Roll Forming Machine, Metal Stud Roll Forming Machine, Stud Roll Forming Machine, To get more information about us as well as see all our products and solutions, you should visit our website. To get more information you should feel free to let us know. Thank you very much and wish your business always be great!

The c channel roll former c keel making machine is the main equipment for the production of light steel. It is formed by cold forming of steel or steel, and is rolled to produce light keels of various specifications.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

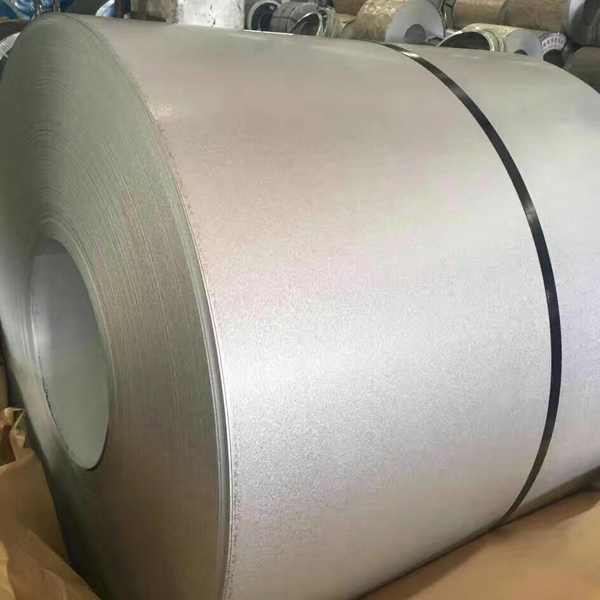

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

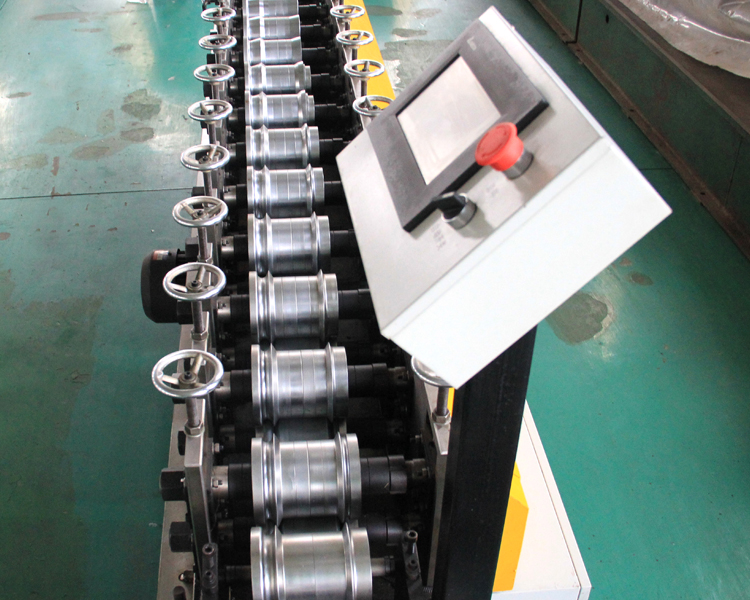

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

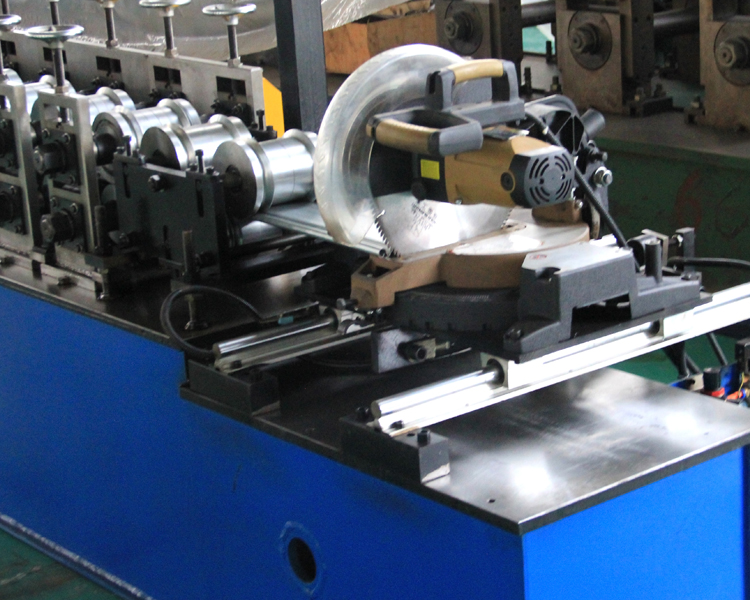

Ceiling c channel making machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our Service Advantage

1. Professional: rich experience in product and export process!

2. Low price: Save your money from every part!

a. Low labor cost;

b. Convenient transportation;

c. Complete supporting industries.

Product detail pictures:

Related Product Guide:

‘A crunch. A rip. Pain spread like a stain’: my lifetime of back trouble | Maggie O’Farrell | News | Steel Downpipe Roll Forming Machine

Blackjack’s Rise And Fall Shows What Drives Customers Away | Steel Downpipe Roll Forming Machine

Fast delivery Automatic Decoiler For Roll Forming Machine - OEM Customized Metal Stud Roll Forming Machine Light Keel Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Wholesale Dealers of Decoiler Production Line -...

-

Fixed Competitive Price Roof Panel Roll Fomring...

-

Factory directly Roof Tile Roll Forming Machine...

-

Wholesale Price China T Grid Ceiling Cold Roll ...

-

Factory Outlets Wall Panel Roll Forming Line -...

-

Newly Arrival Coated Steel Coil - Steel Profil...