Our solutions are broadly identified and trusted by buyers and might fulfill continuously changing economic and social wants of Factory wholesale Roof Tiles Making Machine India/roof Tile Machine For Sale, Be sure to experience free to make contact with us at any time. We’re going to reply you when we receive your inquiries. Please note that samples are available before we start our business.

Our solutions are broadly identified and trusted by buyers and might fulfill continuously changing economic and social wants of Metal Roofing Machines For Sale, Roof Tile Machine For Sale, Roof Tiles Making Machine India, We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are definitely good and knowledgeable about our prodcuts.

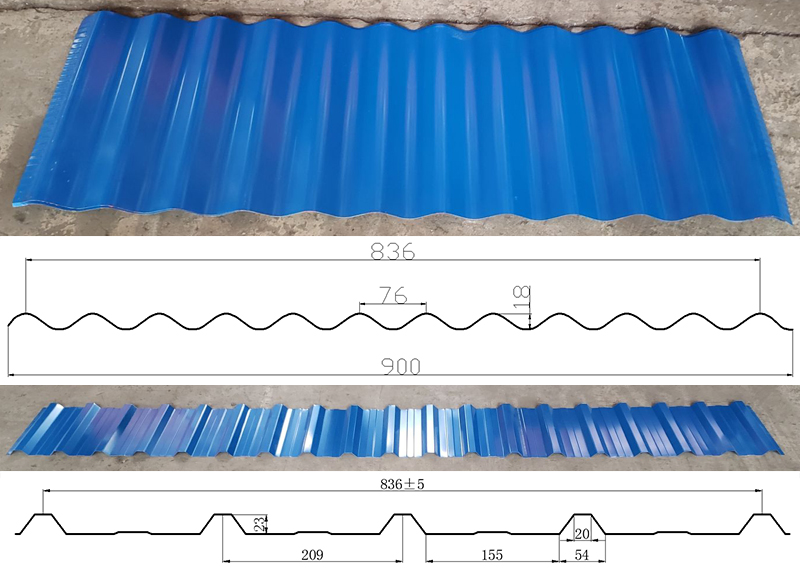

Double Layer Roof Tile Making Machine details showing

This machine can produce two different types of metal tile products. The upper layer of the machine can form corrugated tiles, and the lower layer of the machine can form trapezoidal tiles. The final product is as follows:

Double Layer Roof Tile Making Machine Technical Parameters (some depend on the final design)

| Style | 836-816 Double roof roll forming machine for Bolivia |

| Machine dimension | 8000*1650*1750mm |

| Total weight | 6800kgs |

| Forming steps | Up layer: 13rows; Down layer: 13rows |

| Forming speed | 10-15m/min |

| Hydraulic station power(KW) | 4kw |

| Diameter of shaft | 70mm |

| Hydraulic pressure | 18-20 MPa |

| Electric condition(Voltage ) | 380V/3Phase/50HZ (or based on customer’s need, for example, 220V 440V 415V or 2Phase 60HZ ) |

| Suitable to process | Color steel plate(G330 or G350 ) galvanized steel coil |

| Manual uncoiler max capacity | 5000kgs |

| Control system | PLC |

| Raw material thickness | 0.3-0.8mm |

| Effective width | 836mm and 816mm |

| Material width | 1000mm and 1000mm |

| Main motor | 5.5Kw |

| Material of the cutting blade | Cr 12 quenched treatment 58℃-62℃ |

| Main Shaft Material | 45# steel with finish turning |

| Roller materials | 45# Forging Steel with Chromium Plate |

| Machine Under Frame | 400 H beams and sidewall 18mm |

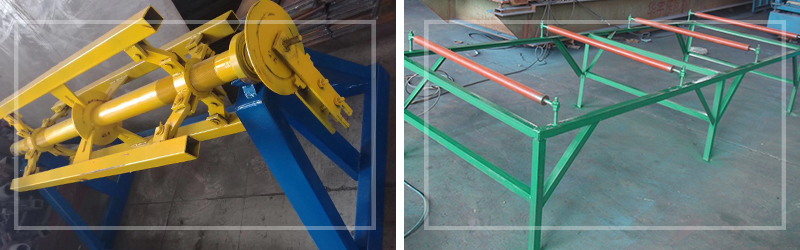

Components of double layer roof roll forming machine

| Manual uncoiler | 1 set | Post-cutting equipment | 1 set |

| Sheet guiding equipment | 1 set | Hydraulic station | 1 set |

| Roll forming system | 1 set | Electric controlling system | 1 set |

| Pressing device | 1 set | Support table | 2 pieces |

We offer our customers easy-broken parts for free.

Application

Roof roll forming machinery could produce metallic roofing tile, trapezoidal or sinusoidal roofing sheet, floor deck, C and Z purlin, expressway guardrail, channel and stud, roller shutter and sandwich panel, etc. Customized profiles and requirements are acceptable, and assistant equipment such as hydraulic decoiler, auto stacker, etc.

Our company

We are professional! Our factory has extensive experience in product and export processes.

We have an ultra-low price advantage! Our factory helps you save money from many details:

1, lower labor costs.

2, convenient transportation.

3, perfect supporting industry.

FAQ

Q: How is this machine’s service life?

A: In the normal maintenance, the service life at least 8 years.

Q: Can you be responsible for transport?

A: Yes, please tell me the destination port or address. We have rich experience in transport.

Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q: How many workers operate this machine to manufacture?

A: Only 1-2 worker.

Q: Can you supply the raw materials?

A: Yes, we can supply the galvanized steel coil, galvalume steel coil, color steel coil, and aluminum coil.

Q: Why choose your company’s products?

A: Because of our products cost-effective, not only high quality and affordable.

-

1000 Trapezoidal Metal Sheet Roll Forming Machine

-

2019 High Quality Glazed Tile Making Machinery ...

-

2019 Hot Dipped Galvanized Steel Coil

-

4 Meters Hydraulic Roof Sheet Bending Machine

-

5/7/8/10/15T sheet metal automatic hydraulic de...

-

762 Corrugated Roof Metal Sheet Roll Forming Ma...

-

850 model corrugated metal PPGI roof sheet roll...