Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for Factory wholesale Best sell ! Color Stone coated roof tile machine/ stone coated glazed steel roofing making machine, We, with open up arms, invite all intrigued prospective buyers to visit our web page or get in touch with us specifically for additional info.

Our primary objective is usually to offer our shoppers a serious and responsible small business relationship, offering personalized attention to all of them for , You can always find the solutions you require in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We’re looking forward to work with you for a win-win situation.

Our Steel Colored Stone Coated Production Line meets the diverse requirements of our customers.

The Steel Colored Stone Coated Production Line is described in detail as follows:

NO. 1 Auto bottom glue spraying section

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements) |

| Automatic pressure spray tank | 1set; Capability:200kg; Range:0.6~1Mpa |

| Automatic glue machine motor | Servo motor; Power:750w; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set; Power: 200w |

| Damp proof lamp | 1 pcs; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set; Power: 7.5kw |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Agitator | 1 set; Power: 1.5kw |

NO. 2 Auto stone coated section

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

NO. 3 The first time drying section

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

NO. 4 Auto face glue spraying section

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pcs; Power:100w |

| Automatic pressure spray tank | 1 set; Capability: 200kg; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Automatic glue machine motor | Servo motor; Power: 750w |

NO. 5 The second time drying section

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

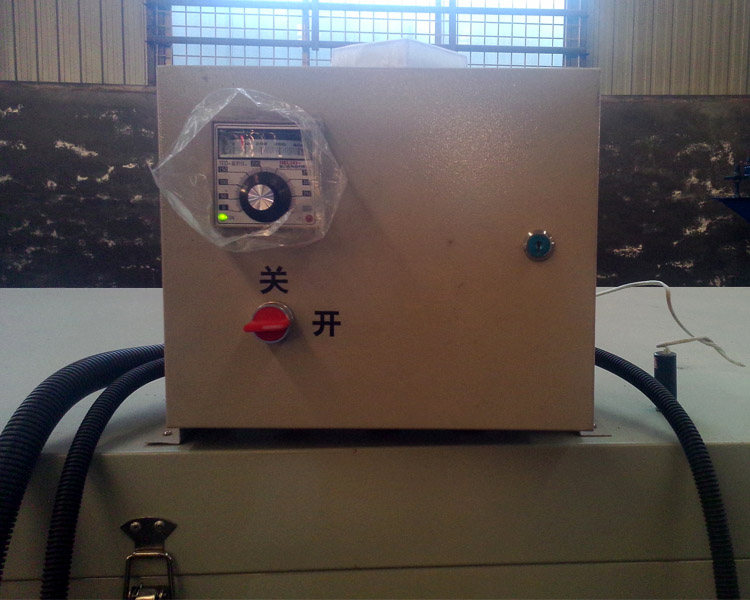

Machine Photos:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Supply OEM/ODM China High Speed Corrugated Roof...

-

Big Discount C Z purlin steel plate roll formin...

-

Wholesale OEM/ODM Light Steel Frame Keel Making...

-

Factory Price China 312 High Quality Ridge Cap ...

-

Wholesale Semi-automatic Aluminum Sheet Slittin...

-

Lowest Price for Trapezoid Galvanize Aluminium ...