Our firm sticks on the theory of “Quality will be the life in the enterprise, and status could be the soul of it” for Factory Selling Emm29-197various Roof Profile Making Machine, We are willing to give you the lowest price in the market, best quality and very nice sales service.Welcome to do bussines with us,let’s be double win.

Our firm sticks on the theory of “Quality will be the life in the enterprise, and status could be the soul of it” for Metal Roofing Machines For Sale, Used Roll Forming Machine, Various Roof Profile Making Machine, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it’s easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

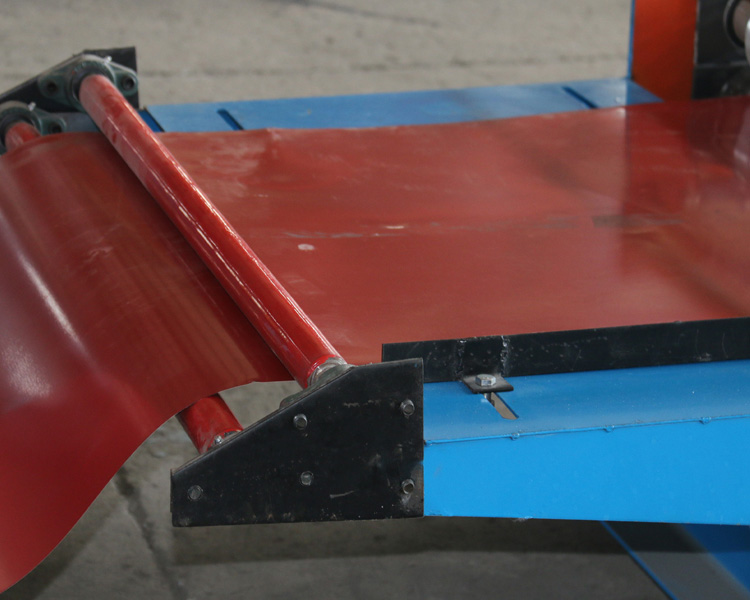

The tiles pressed out by the glazed roofing tile roll forming machine are very beautiful, and the technical parameters of the machine are as follows:

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Glazed roofing tile roll forming machine components include: Manual un-coiler, Guiding platform, Coil strip leveler, Main machine of roll forming, Electric-motor, Cutting device, Hydraulic station, PLC control and Supporter table.

Machine Details:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Metal profile light keel roll forming machine

-

Supply OEM/ODM China Steel Light Keel Plate Rol...

-

Factory Cheap Hot Slitting Machinery for metal ...

-

Massive Selection for China Double Layer Floor ...

-

OEM/ODM Supplier Steel Door Window Frame Roll F...

-

Factory directly 2018 Metal Roofing Glazed Tile...