“Control the standard by the details, show the power by quality”. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Factory Promotional Metal Roofing Galvanized Aluminum Corrugated Steel Sheet Making Machine Colored Steel Wall Roof Panel Cold Roll Forming Machine, Our corporation insists on innovation to promote the sustainable enhancement of enterprise, and make us become the domestic high-quality suppliers.

“Control the standard by the details, show the power by quality”. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Colored Steel Wall Roof Panel Cold Roll Forming Machine, Metal Roofing Galvanized Aluminum Corrugated Steel Sheet Making Machine, Metal Roofing Galvanized Aluminum Wall Roof Panel Cold Roll Forming Machine, By integrating manufacturing with foreign trade sectors, we can deliver total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified goods and the control of the industry trend as well as our maturity before and after sales services. We’d like to share our ideas with you and welcome your comments and questions.

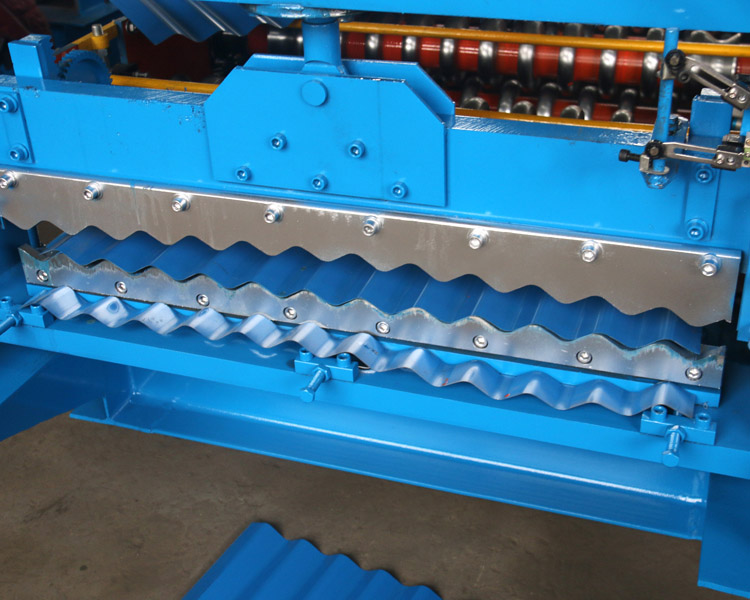

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

OEM Factory for Ss And Aluminum Auto Channel Le...

-

Fixed Competitive Price Hot Sale Cold Rolled Co...

-

Wholesale OEM/ODM Jlsh1218-400w-f Laser Dieboar...

-

Wholesale Price China Dixin Metal Roof Curving ...

-

Wholesale Discount Automatic Galvanized Metal R...

-

Supply OEM Hot sale high quality high frequency...