We pursue the administration tenet of “Quality is superior, Services is supreme, Standing is first”, and will sincerely create and share success with all customers for Factory Promotional China Stone Coated Metal Roof Tile Machine, Our products and solutions delight in fantastic popularity among the our buyers. We welcome prospects, company associations and close friends from all areas of your world to get in touch with us and seek out cooperation for mutual gains.

We pursue the administration tenet of “Quality is superior, Services is supreme, Standing is first”, and will sincerely create and share success with all customers for China Stone Coated Steel Roof Tile Roll Formingmachine, Stone Coated Metal Roll Forming Machine, If you need any of our merchandise, or have other products to be produced, be sure to send us your inquiries, samples or comprehensive drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

Our Steel Colored Stone Coated Production Line meets the diverse requirements of our customers.

The Steel Colored Stone Coated Production Line is described in detail as follows:

NO. 1 Auto bottom glue spraying section

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements) |

| Automatic pressure spray tank | 1set; Capability:200kg; Range:0.6~1Mpa |

| Automatic glue machine motor | Servo motor; Power:750w; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set; Power: 200w |

| Damp proof lamp | 1 pcs; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set; Power: 7.5kw |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Agitator | 1 set; Power: 1.5kw |

NO. 2 Auto stone coated section

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

NO. 3 The first time drying section

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

NO. 4 Auto face glue spraying section

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pcs; Power:100w |

| Automatic pressure spray tank | 1 set; Capability: 200kg; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Automatic glue machine motor | Servo motor; Power: 750w |

NO. 5 The second time drying section

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

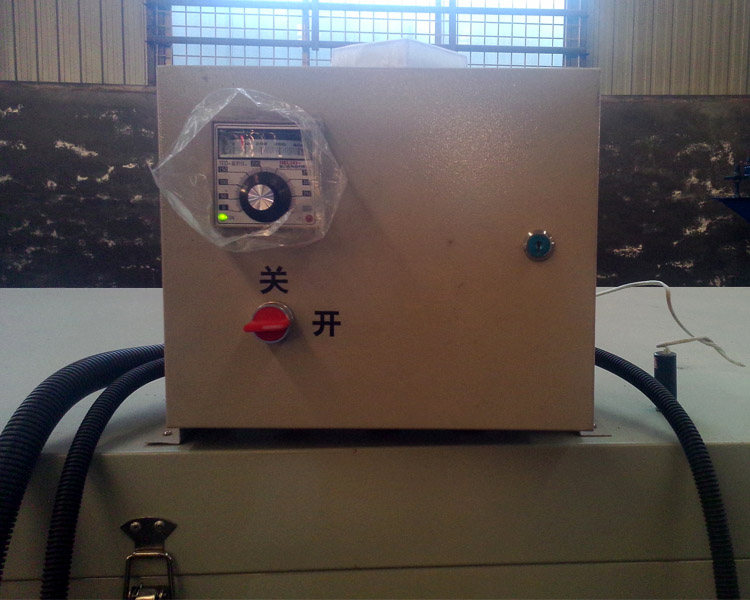

Machine Photos:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

China Cheap price China Sheet Metal CNC Hydraul...

-

Personlized Products Special Multi-function Pro...

-

Wholesale OEM China Trapezoidal Roof Panel and ...

-

Factory Selling China Standing Seam Roof Panel ...

-

2019 Latest Design China Zimbabwe Customer Orde...

-

PriceList for Light Steel Keel Roll Forming Mac...