We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Factory Price For Supermatic 840/850/890 Three Layer Relabile And Stable Performance Corrugated Iron Roofing Steel Sheet Making Machine, Customer pleasure is our main objective. We welcome you to set up business relation with us. For even further information, make sure you will not wait to contact with us.

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for 840/850/890 Three Layer Sheet Making Machine, Roofing Sheet Making Machine, Steel Sheet Making Machine, The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

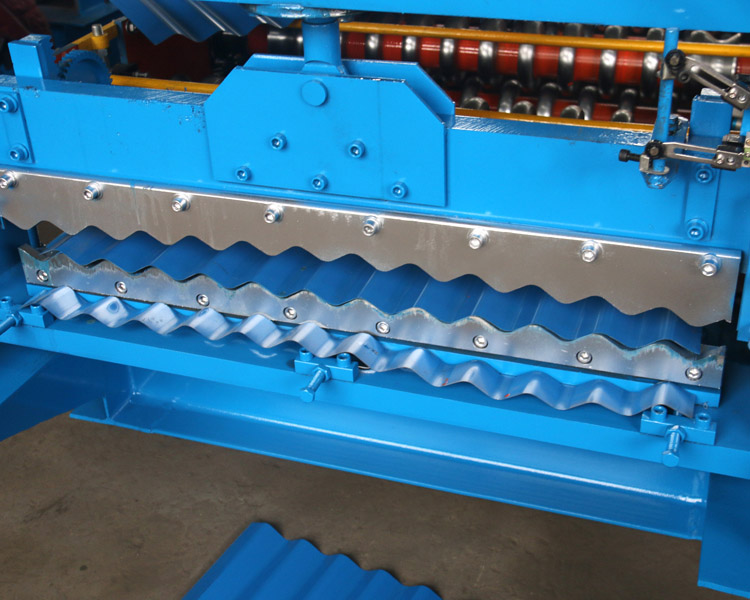

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.