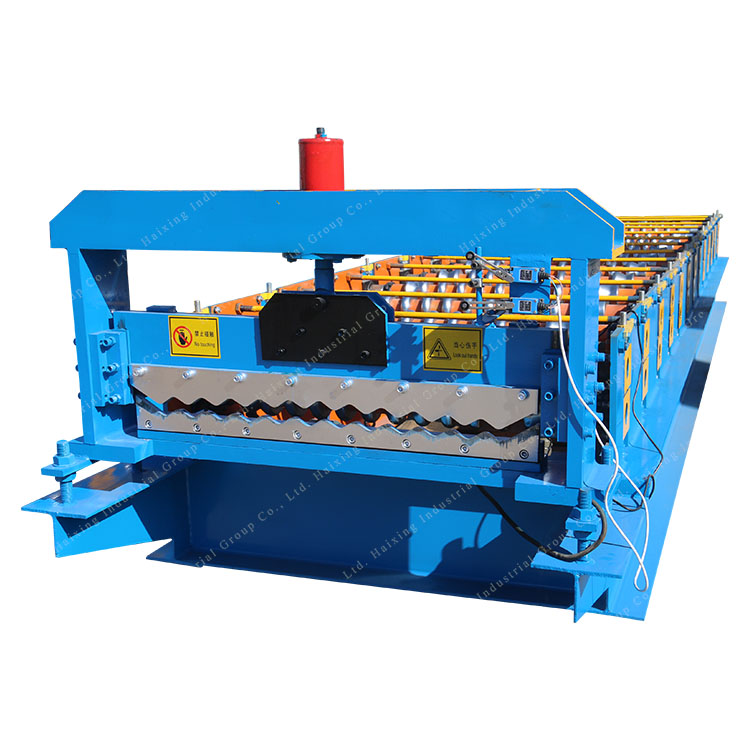

We persist with our business spirit of “Quality, Effectiveness, Innovation and Integrity”. We aim to create a lot more value for our consumers with our wealthy resources, sophisticated machinery, experienced workers and outstanding providers for Factory Outlets Roofing Top Sheet Galvanized Steel Curving Machine Corrugated Glazed Tile Metal Roofing Sheet Making Machine, We are able to customize the merchandise according in your prerequisites and we will pack it in your case when you purchase.

We persist with our business spirit of “Quality, Effectiveness, Innovation and Integrity”. We aim to create a lot more value for our consumers with our wealthy resources, sophisticated machinery, experienced workers and outstanding providers for Steel Sheet Profile Roll Forming Machine Tile Type Roll Forming Machine Roofing Sheet Making Machine, Tile Roof Sheet Steel Roof Tiles Cold Roll Forming Machine Wall Panel Sheet Roll Forming Machine Curving Roof Machine, Tile Roofing Roll Forming Machine Wall Sheet Metal Roll Forming Machine Roof Panel Curving Machine, Now we have more than 8 years of experience in this industry and have a good reputation in this field. Our products have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

hydraulic press steel roof tile making machine Technical Parameters

| Style | metal roof panel roll forming machine |

| Machine dimension (mm) | 6500*1500*1200 |

| Total wight (Kg) | 3500 |

| Forming steps | 13 rows |

| Forming speed (m/min) | 8-12 |

| Hydraulic station power(Kw) | 4 |

| Diameter of shaft (mm) | 75 |

| Hydraulic pressure(MPa) | 18-20 |

| Electric condition | 380V/3Phase/ 50HZ |

| Suitable to process | Color steel plate(G330 or G350) |

| Decoiler max capacity (Kgs) | 10000 |

| Control system | PLC |

| Raw material thickness (mm) | 0.3-0.8 |

| Effective width(mm) | 750 |

| Material width(mm) | 1000 |

| Main application | tile roof |

Our Advantage

1. Our machine motor are GERMAN BRAND SIEMENS;

2. Our roller spacer are 4 mm thick seamless steel pipe;

3. Our output table can be adjust height according customer demands;

4. Our PLC control console can be look around 360 degree;

5. All easy-broken pars can be change within 14 month in free.

-

10% discount 850 model corrugated metal roof sh...

-

201 Steel Cold Roll Stainless Aluminum Coil

-

10 tons hydraulic decoiler

-

2019 Canton Fair Hot sale Fully Automatic Trape...

-

4 Meters Hydraulic Roof Sheet Bending Machine

-

5t/7t/10t Auto Hydraulic Decoiler With Car

-

690mm Galvanized Steel Sheet Floor Decking Pane...