factory Outlets for Metal Stud C Channel U Purlin Roll Forming Machine - Sheet Metal Bending Machine – Haixing Industrial Detail:

|

Sheet metal bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

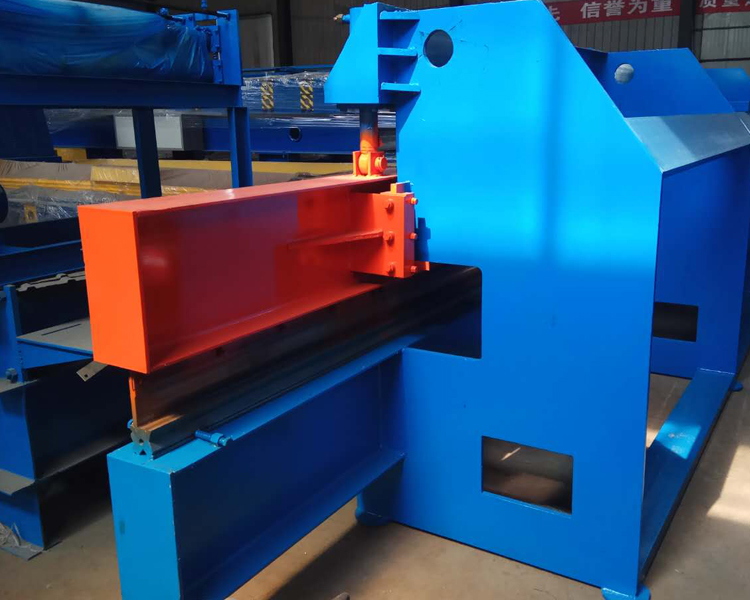

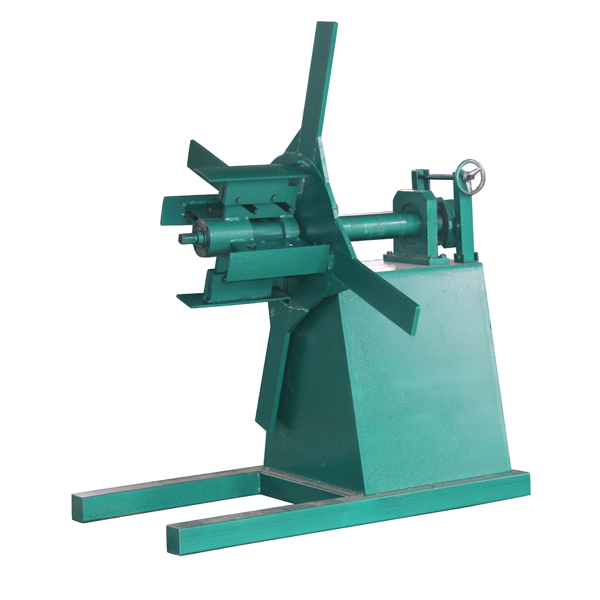

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Service:

a. 18 months guarantee for the whole machine.

b. 24 hours technical support by email or calling

c. If there is any problem found of the machine, we will repair it for free in one year.

Product detail pictures:

Related Product Guide:

Oden Technologies raises $10M to bring data analytics to manufacturing | Roof Sheet Curving Machine

The Incredible True Story of the Henrietta C. | Floor Deck Macking Machine

factory Outlets for Metal Stud C Channel U Purlin Roll Forming Machine - Sheet Metal Bending Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Factory Cheap Steel Shutter Gate Frame Machine ...

-

China Factory for Customized C Purlin Roll Form...

-

Short Lead Time for Corrugated Steel Sheet Wall...

-

Factory directly Small Gutter Machine - 5 Ton ...

-

One of Hottest for Roof Color Steel Panel Makin...

-

Leading Manufacturer for Downspouts Steel Sheet...