factory Outlets for High-Speed Curving Machine - Quoted price for Double Layer Roof Panel Roll Forming Machine – Haixing Industrial Detail:

“Control the standard by the details, show the energy by quality”. Our enterprise has strived to establish a hugely efficient and stable staff members staff and explored an effective good quality control procedure for Quoted price for Double Layer Roof Panel Roll Forming Machine, Our products are new and old customers consistent recognition and trust. We welcome new and old customers to contact us for future business relations, common development. Let’s speeding in the dark!

“Control the standard by the details, show the energy by quality”. Our enterprise has strived to establish a hugely efficient and stable staff members staff and explored an effective good quality control procedure for Double Layer Roll Forming Machine, Roll Forming Machine, Roof Panel Roll Forming Machine, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

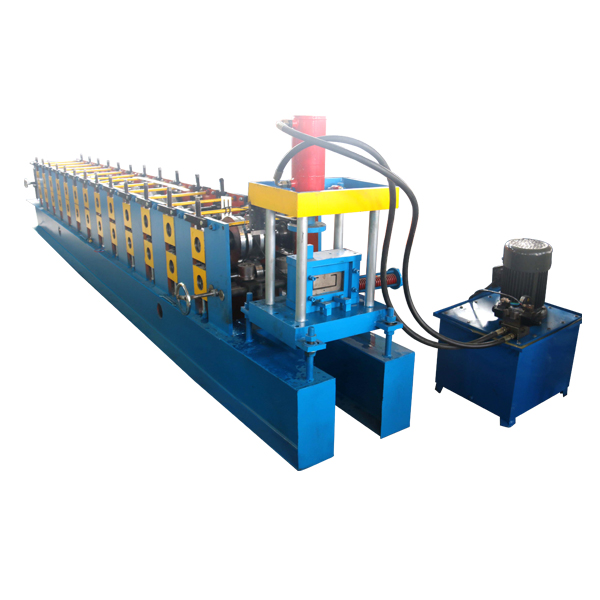

Parameters of steel double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

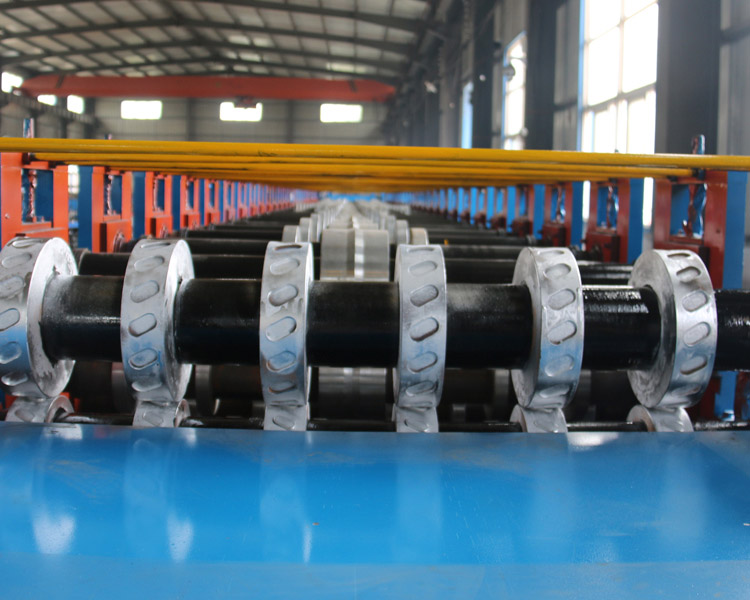

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

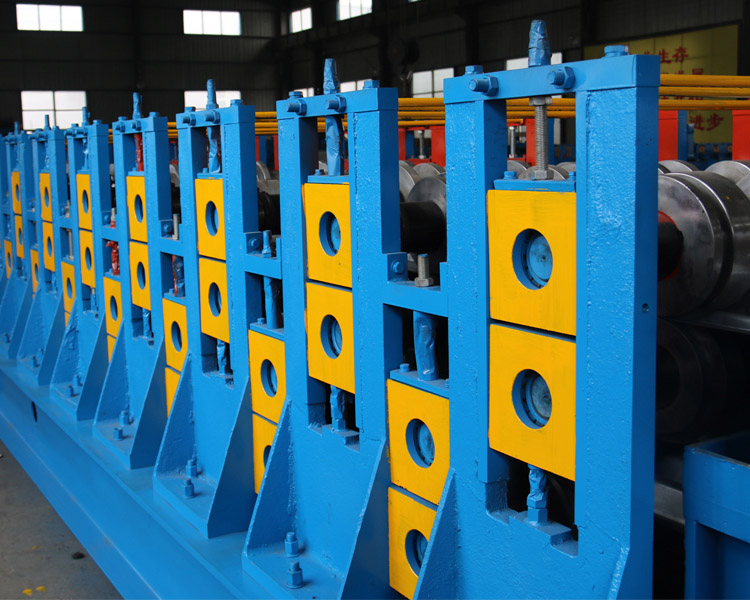

Product detail pictures:

Related Product Guide:

Royal Caribbean Symphony of the Seas suites in photos | Steel Downpipe Roll Forming Machine

Transforming buildings into icons - Nikkei Asian Review Arrow Artboard Artboard Title Chevron Cross Eye Icon Icon Facebook Icon Linkedin Shape Icon Mail Contact Path Layer Icon Mail Menu Burger Positive Arrow Icon Print Icon Search Si | Decoiler In Color Coating Line

factory Outlets for High-Speed Curving Machine - Quoted price for Double Layer Roof Panel Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Low MOQ for Stainless Steel Roller Shutter Door...

-

2017 New Style Roof Cold Forming Machine - Hyd...

-

China Factory for Electric Decoiler For 10 Ton ...

-

Short Lead Time for Metal Roof Sheet Bending Ma...

-

Special Price for Rain Gutter Roof Tile Machine...

-

Discount wholesale Round Gutter Roll Forming Ma...